300 mm Resist-Torr Photoresist Detection Monitor for High Pressure Degas

Overview

The 300 mm Resist-Torr consists of an optimum combination of a closed ion source quadrupole mass analyzer with fast response capillary inlet, together with advanced proprietary algorithms developed exclusively for the degas chambers on industry leading 300 mm PVD cluster tools. When utilized with the powerful features of Process Eye™ and TOOLweb RGA sensor control software package, the result is completely automated operation and highly reliable photoresist detection. Unscheduled downtimes are reduced and device yields are improved.

- Detection of photoresist contamination during high pressure (~8 Torr) degas

- Fully automated process monitoring means no operator necessary

- Calculation of PR Index - a measure of photoresist contamination level

- Built in calibration standard with automatic calibration routine enables long-term data comparison and proper system operation

- Variable alarm sensitivity to match the conditions of your product in your fab or process tool

- Powerful optional data review feature to maximize ROI

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

300MM-RESIST-TORR Photoresist Detection Monitor, 300 mm Resist-Torr® |

|

Specifications

-

Mass Range1-200 amu

-

Ion SourceHigh sensitivity, closed ion source

-

FilamentsReplaceable twin Thoria filaments

-

Mass FilterDouble filter (1 inch "RF only" pre-filter with 4 inch main filter)

-

DetectorDual (Faraday and Secondary Electron Multiplier)

-

Minimum Detectable Concentration<100ppb for all common gases except <10ppm for H2

-

Mass StabilityBetter than ±0.1 amu over 8 hours

-

ResolutionBetter than 10% valley between peaks of equal height throughout the mass range

-

Mounting Flange2.75 inch Conflat® flange, SS capillary

-

Vacuum Hardware60 l/s turbomolecular pump with high conductance analyzer housing, fast response capillary inlet system, automated vacuum controller (RVC) completely interlocked and integrated

-

Analyzer Housing Base PressureBetter than 5x10-9 Torr after bakeout

-

Bakeout Temperature and Bakeout JacketIncluded for 200°C bakeout

-

Operating TemperatureElectronics: 10-40°C

-

Pneumatics60-80 psig CDA

-

Power Requirements88-264 VAC, 47/63 Hz, 600 Watts

-

Maximum Operating Conditions80% RH (non condensing)

-

LED Status IndicationInterlock status, filament emission, SEM, power and communications

-

I/O Capability4 analog inputs and 2 outputs (plus 1 dedicated gauge input). Optional support for a large number of both analog and digital inputs and outputs, including relay control

-

Other FacilitiesLeak check headset socket, external filament trip socket, instrument reset

-

SoftwareProcess Eye Professional fully network compatible control platform generating under 32bit or 64bit Microsoft® Windows® xP, Vista, Server 2008 or Windows 7 (recommended)

-

CommunicationEthernet CAT-5e

-

PC RequirementsIntel® Pentium IV® or AMD Athlon xP 1.2GHz, 1GB RAM, 120 GB hard drive, dependent upon total number of sensors on the computer and the operating system in use.

-

Simultaneous Multi-SensorProcess Eye Professional client/server configuration offers flexible multi-sensor operation

-

RGA to Vacuum System Cable Length33 feet (10 m)

-

Shipping Weight85 pounds (38.5 Kg)

-

Foreline PumpDry diaphragm standard

-

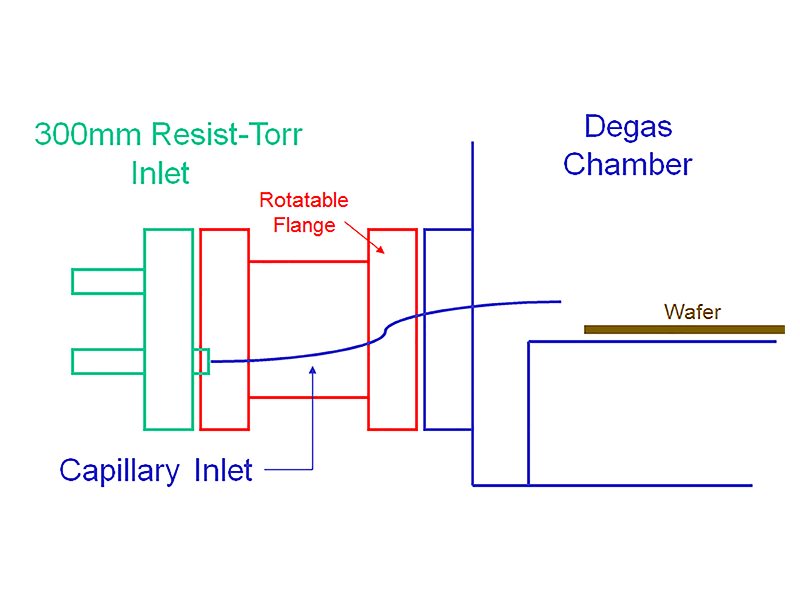

InletDual path with fast-response capillary for degas monitoring and high conductance for base vacuum. Includes heater jacket.

Features

Detection of Photoresist Contamination

Installation Schematic

It is often difficult to know when a photoresist problem is affecting the productivity of a 300 mm PVD system. Even small amounts of residual resist, when introduced over a prolonged period, can reduce yields, cause particle contamination or slowly contaminate process chambers, thereby requiring premature kit changes. Major photoresist hits can be very costly, upwards of hundreds of thousands of dollars for lost wafers, especially if the tantalum/copper target becomes contaminated.

Resist can be inadvertently introduced to PVD systems in a number of ways. Rushing Hot Lots through opens the door to skipping steps like the resist strip or even the complete etch and strip cycle. This could result in contamination throughout the process tool if the wafer is not stopped at the degas chamber. Such process flow errors can impact PVD tool performance, immediately, from a single wafer. More common, however, is the incomplete removal of resist. This can happen due to a poorly controlled end point in the asher such as from firstwafer, cold-chamber effects, or from faults on integrated etch/strip tools.

Each of these mechanisms can leave resist contamination on wafers which eventually is seen as a loss of die or high particle densities in sputter etch process chambers. Resist contamination can be the cause of a series of factors, all of which work to reduce tool availability, increase COO, and decrease the overall yield of a process flow.

Calculation of the PR Index

The 300mm Resist-Torr considers many different parameters of the degas step and combines that data to provide information in the form of a meaningful number, without the need for user-interpretation. This measurement, termed the PR Index, is a normalized measure of wafer borne photoresist contamination that can be presented in various forms to compare data over time.

The 300mm Resist-Torr can interrupt the processing of any wafer automatically, without operator intervention, if a wafer enters the vacuum system with detrimental levels of residual photoresist, as determined by the PR Index.

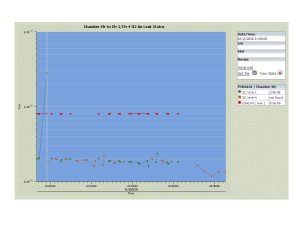

PR Index trace for wafer sequence run at a foundry with interspersed normal and known PR contaminated wafers; red (alarm) and yellow (warning) lines show the default control limits PR Index trace for a series of test wafers run at a 300mm PVD tool OEM. The PR hit event was much longer than the preceding normal wafers because the tool was stopped on that wafer.

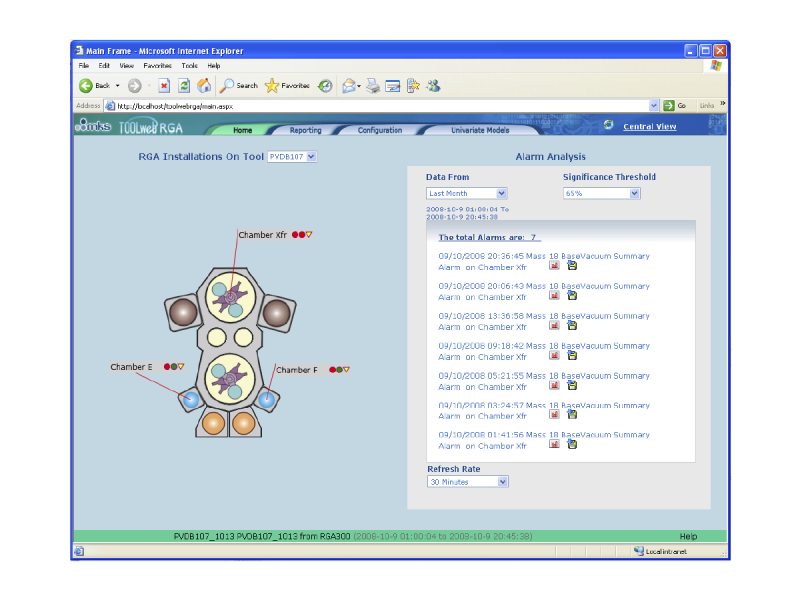

TOOLweb® RGA

Using TOOLweb RGA sensor integration option for process tools, the 300mm ResistTorr can be used as a degas chamber sensor in a completely automated process environment. TOOLweb RGA maintains a constant monitor of tool activities with all sensor data being framed by wafer logistics before alarm models are applied. Full alarm and data reporting to the FAB host and FDC are available so real time monitoring of chamber conditions and flagging of any process excursions from ideal conditions is possible.

Resources

Drawings & CADs

- 300mm Resist-Torr® Dimensional Drawing (176.6 kB, PDF)

Literature

- 300mm Resist-Torr for High Pressure Degas (335.5 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity