CRV Corrosion Resistant Vacuum Isolation Valve

Overview

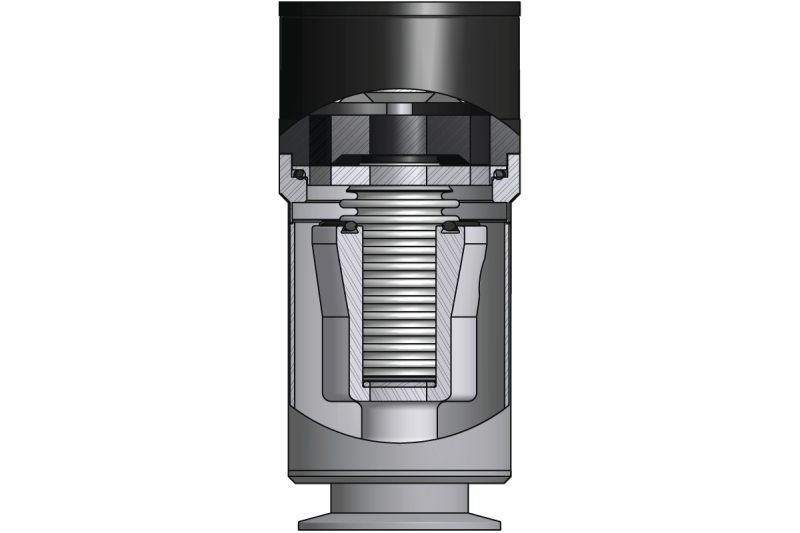

Corrosion resistant valves employ a patented technology to completely seal off the valve bellows while the valve is in the open processing position. A unique umbrella valve (vent valve) can be used to exhaust trapped gases if applicable. Manufactured using superior techniques and high-quality materials, the CRV Corrosion Resistant Vacuum Isolation Valve is extremely durable and dependable. It has a small profile, is light, low in cost and is easy to maintain.

- NW40 - NW50, custom sizes available

- Designed for use in harsh environments

- Shield keeps reactive and corrosive gases from contacting bellows

- Normally closed valve utilizes air to open and spring to close for safety

- High purity, 6061 aluminum, 304 and 316 stainless steel materials, to minimize corrosion

- Easily accommodated into existing systems, using industry standard dimensions

Products

Configuration Options

The following options are available for CRV Corrosion & Ozone Resistant Compact Vacuum Valves

Ordering Code Example: CRV-40-AK-AN-NVXXX

| Configuration Option | Option Code |

|---|---|

| CRV Vacuum Isolation Valve | CRV |

| Flange Size | |

| NW40 | 40 |

| NW50 | 50 |

| Body Configuration | |

| Angle | A |

| Inline | I |

| Flange Type | |

| ISO-KF | K |

| Shield Configuration | |

| Aluminum no vent | AN |

| Aluminum with vent | AV |

| Stainless Steel no vent | SN |

| Stainless Steel with vent | SV |

| Limit Switch | |

| Limit Switch | L |

| No Limit Switch | N |

| Seal Type | |

| Viton® | V |

| Kalrez® | K |

| Chemraz® | Z |

| Perlast® | P |

| Gumlast® | G |

| Heater | |

| No Heater | XXX |

| Angle Body Heater | R6A |

| In-line Body Heater | R6I |

| Angle Body LTA Heater | L6A |

| In-line Body LTA Heater | L6I |

| Solenoid | |

| 12 VDC | 12D |

| 24 VDC | 24D |

| 24 VAC 50/60 Hz | 24A |

| 120 VAC 50/60 Hz | 120 |

| 240 VAC 50/60 Hz | 240 |

| 1/8 inch NPT | None |

Specifications

-

TypeCorrosion & Ozone Resistant Bellows-sealed Isolation Valve

-

Vacuum RangeAtmosphere to 1.0 x 10-9 Torr

-

Port SizeNW40, NW50

-

Helium Leak Rate1.0 x 10-9 std cc/sec

-

Cylinder Volume2.2 - 6.4 in3, depending on configuration

-

Cylinder Air Pressure90 psig ±30 psig

-

Limit Switch Rating5A - 250 VAC

-

Single Pole, Single Throw5A - 30 VDC

-

Electrical Duty Cycle100 volts 72%

120 volts 50% -

Blow-By PressureNW40: 50 psia

NW50: 45 psia -

Actuation TimeNW40: 270 msec opening, 530 msec closing

NW50: 450 msec opening, 1130 msec closing -

Heater Nominal Set Point170°C (338°F)

-

Heater Interior Range135°-180°C (275°-356°F)

-

Heater MaterialsMolded silicone foam, fiberglass reinforced silicone, Teflon insulated wire

-

Heater Exterior Range60°-70°C (140°-158°F)

-

Heater Foam Thickness0.5 mm

-

Heater ComplianceCE, UL E52951 2JR

-

Heater ConnectorsMidget Twist-Lock, nylon, NEMA ML-1

-

Heater Weight Range0.5 to 1.5 lbs.

-

Power Cord Current12 A maximum

-

LTA Monitor EnclosureBlack plastic

-

LTA Power Requirements90-130 VAC input, 12 VDC ±3 VDC output

-

LTA Power Consumption0.3 W

-

LTA Relay Contact RatingSPDT, 2 A @ 50 VAC resistive, 1 A @ 30 VDC

-

LTA Input/Output WiringThermal switch line IN

Thermal switch line OUT

Normally closed

Common

Normally open -

LTA Dimensions2.58 x 4.76 x 1.46 inches

-

LTA ComplianceCE

-

Typical Life1,000,000 cycles

-

Weight3.5 - 6.4 pounds, depending on configuration

Features

TIG Fusion Welded vacuum Grade Body

Another standard feature is a TIG fusion welded vacuum grade body made of highly, corrosion resistant, 304 stainless steel, creating fewer entrapment areas, resulting in less contamination buildup. The Corrosion Resistant Valve is available in angle and inline configurations. Port sizes include NW 40 and NW 50 using maximum internal diameters for greater conductance. For leak tight operation, elastomer seals are available in Viton® for typical vacuum operating conditions, or Kalrez®, Chemraz®, Perlast® or Gumlast® for higher temperature conditions and increased chemical resistance.

Applications

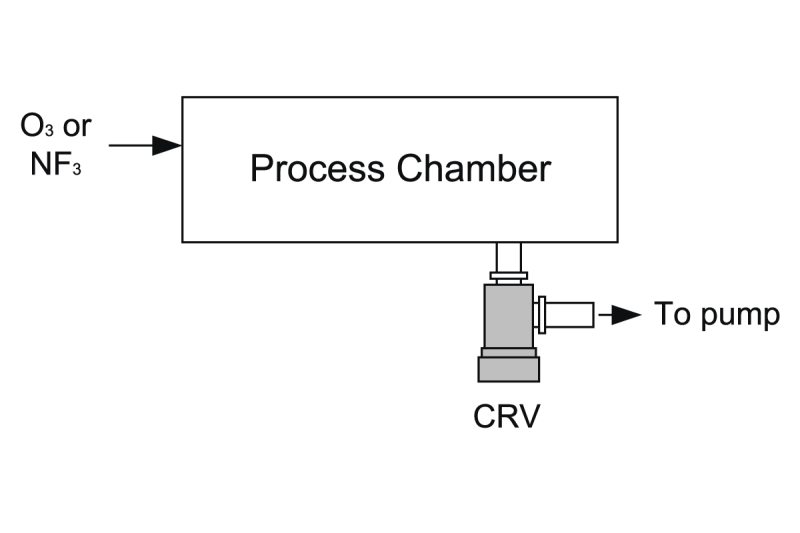

The Corrosion and Ozone Resistant Valve is designed to provide long life in extremely harsh semiconductor or solar processes. This is achieved by shielding the thin wall bellows, limiting bellows exposure to corrosive or reactive gases. Typical processes that require a corrosion resistant valve are CVD and Etch. These processes use gases such as fluorine, chlorine, bromide or ozone. An aluminum shield is recommended for fluorine or ozone while a stainless shield should be used when chlorine or bromide are used. This valve can also be used in exhaust line applications to avoid corrosion of the valve bellows.

Resources

Manuals

- CRV Vacuum Valve Manual (0, PDF)

Ultra-High Velocity

Ultra-High Velocity