AX8575 Stand-Alone High Flow, High Concentration Ozone Delivery System

Overview

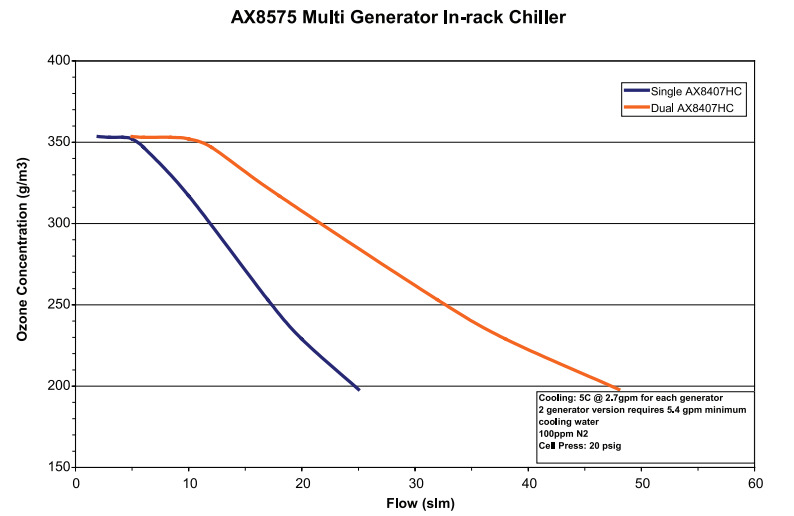

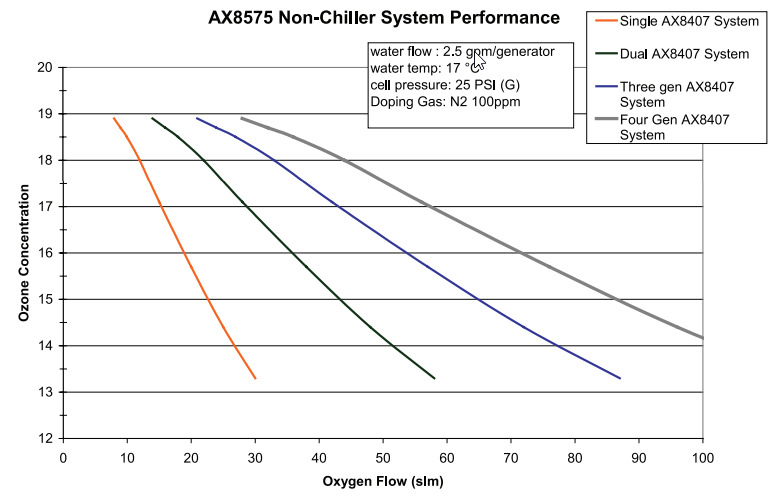

The AX8575 stand-alone ozone gas delivery system is designed to provide high flow, high concentration, ultra clean ozone generation and delivery. This unit has the highest flexibility to meet the ever changing needs of the semiconductor industry. The AX8575 is a fully integrated, high output ozone gas delivery system specifically designed for use with an increasing number of semiconductor process applications such as Atomic Layer Deposition (ALD), Chemical Vapor Deposition (CVD), Tetraethyl Orthosilicate (TEOS)/Ozone CVD (HDSACVD), photoresist strip, wafer cleaning, contaminant removal, and oxide growth. The system can be configured as a multi-channel system delivering ozone for up to 4 channels supporting multiple chambers or multiple tools. The AX8575 is available with an in-rack chiller option for high concentrations. Flow rates of up to 40 slm and concentrations up to 350g/Nm3 can be achieved depending on the configuration of the system.

- Concentrations up to 350g/Nm3 at higher flow rates to meet new process requirements.

- Fast & easy installation with minimal connections.

- Supports single or multiple process tools for efficiency and lower cost of operation.

- Flexible - each channel can be process matched individually.

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

AX8575 Ozone Delivery Subsystem, 40 slm Ozone Delivery Subsystem, In-rack Chiller |

|

Specifications

-

TypeOzone Gas Delivery System

-

Ozone Output350g/Nm3

-

Flow Rate40 slm

-

Feed GasOxygen, Nitrogen (20 - 100 ppm of total flow)

-

Feed Gas Supply Pressure50 psig (3.5 kg/cm2) nominal, 60 psig (4.2 kg/cm2) maximum, N2 pressure 10 psi higher than O2 pressure

-

Feed Gas Purity99.9995% minimum

-

Operating Temperature41 - 104°F (5 - 40°C)

-

Cooling Water Temperature Required12 - 21°C with chiller, 5 - 17°C without chiller

-

Cooling Water Filtration Required100 micron Filtration PWC (with chiller)

-

Cooling Water Quality Required1 - 3 MOhm DI, Note: Max DI water/Glycol blend: 70/30

-

Cooling Water Minimum Flow Required10 gpm nominal (water modulating valve range: 2 - 10 gpm) with chiller, 2.5 gpm per Generator (configuration dependant) without chiller

-

Cooling Water Connections Required1 in. compression (Swagelok®)

-

Cooling Water Heat Load Required10 kw (based on two generator configuration) with chiller, 5 kw per generator without chiller

-

Voltage Requirements208 volts AC (±10%), three phase

-

Current Requirements31 Amps RMS, 50 Amps service (depending on configuration) minimum of 10,000 A.I.C, 60 Amps service with chiller

-

Frequency50/60 Hz

-

Exhaust Flow Rate150 cfm (70.8 l/s)

-

Exhaust TypeSEMI Category 4 (accidental or emergency release of hazardous gas or vapor)

-

Exhaust Static Pressure0.10 in. (2.54 mm) H2O minimum, measured at the bottom of the duct flange adapter on cabinet

-

Control Air Pressure70 - 100 psig

-

Control Air TypeCDA or dry nitrogen, 40µm filtered

-

Control Air Fitting1/4 in. compression (Swagelok®)

-

Exhaust Connection6 in. diameter duct opening or 4 in. diameter duct opening

-

Dimensions24 x 75 x 36 in. (610 mm x 1575 mm x 914 mm) (width x height x depth)

-

Relative Humidity30 - 90% (non - condensing)

-

Weight600 lbs.(272 kg) for system with one generator, 880 lbs.(400 kg) for system with four generators, 1100 lbs. (499 kg) for system with two generators and internal chiller

-

ComplianceCE, S2 - 0302, F47

-

AltitudeUp to 3280 feet (1000 m) above mean sea level

Features

Environmentally Friendly Solution

Ozone has many advantages over other oxidizers as a strong oxidizing agent. Ozone has a high redox potential, can be generated at the point-of-use, and it decays naturally into oxygen (2O3 ⇒ 3O2). Therefore, it is considered a "green" chemical. If required, ozone can also be destroyed at the output of the process chamber using a catalytic or thermal destruct unit. This significantly lowers the chemical disposal cost, as the output is oxygen and contains no ozone. Ozone is very stable at room temperature, making it a good choice for most applications. Typical ozone applications include ALD, CVD, TEOS/Ozone CVD, photoresist strip, wafer cleaning, contaminant removal, surface conditioning, and oxide growth.

Multi-channel Capability

The AX8575 system is configurable with up to four (4) independent channels to support multiple tools or chambers concurrently. Each channel can be matched to the specific concentration and flow required for your specific process. For ultra high concentration processes the system can be configured for up to two (2) channels with an in-rack chiller thereby maintaining the same footprint. The ozone source for each channel is the production-proven AX8407 series ozone generators. It incorporates MKS patented, field proven, high concentration, ultra clean ozone generation technology. The AX8575 includes all subassemblies required for stand-alone operation, including power distribution, an ambient ozone safety monitor and status indicator panel.

Resources

Literature

Drawings & CADs

Application Notes

- Ozone Data Conversion Tables (289.1 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity