Sorry, this family of products is no longer available.

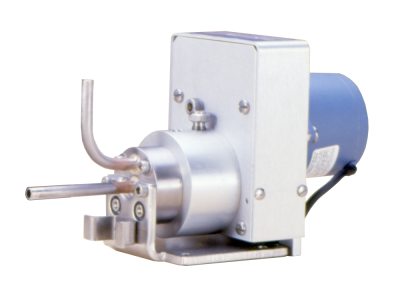

245 Metal-seated Flow Control Valve

Overview

The 245 Valve is an all-metal, bakeable control valve, capable of controlling pressure from 10-11 to 6000 Torr, with a maximum throughput up to 2500 Torr-liters/sec (200 slm). The valve can be used with many corrosive gases that preclude the use of other valves. With the valve driver assembly removed, the valve may be baked to 450°C for UHV applications. The stepper motor used to drive the 245 allows response to pressure or set point changes in fractions of a second, and will drive the valve from a fully closed to a fully open position in only 15 seconds.

Specifications

-

Type245 Metal-seated Control Valve

-

Full Scale Flow Range10-11 to 6000 Torr

-

Closed Conductance Leakage<10-9 scc/sec

-

Maximum Throughput2500 Torr-liters/sec (200 slm)

-

Maximum Inlet Pressure200 psig on center port, 25 psig on other port

-

Exposed Materials304 sst and fine silver

-

Fitting Type1/4 inch (6.35 mm) OD tubulation

-

Operating Temperature0 - 50°C

-

Bake Out Temperature450°C (with driver removed and bakeout clamp installed)

Resources

Literature

- 244E Pressure/Flow Controller and 245 Control Valve (archive) (263.3 kB, PDF)

Manuals

- 244E Pressure/Flow Controller & Type 245 Control Valve Manual (223.4 kB, PDF)

- Series 245 Pressure/Flow Control Valve Assembly Manual (900.8 kB, PDF)

- Series 245 Pressure/Flow Control Valve Quick Start Guide (245002) (794.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity