Virtual Wall™ Nitrogen Process Barriers

Overview

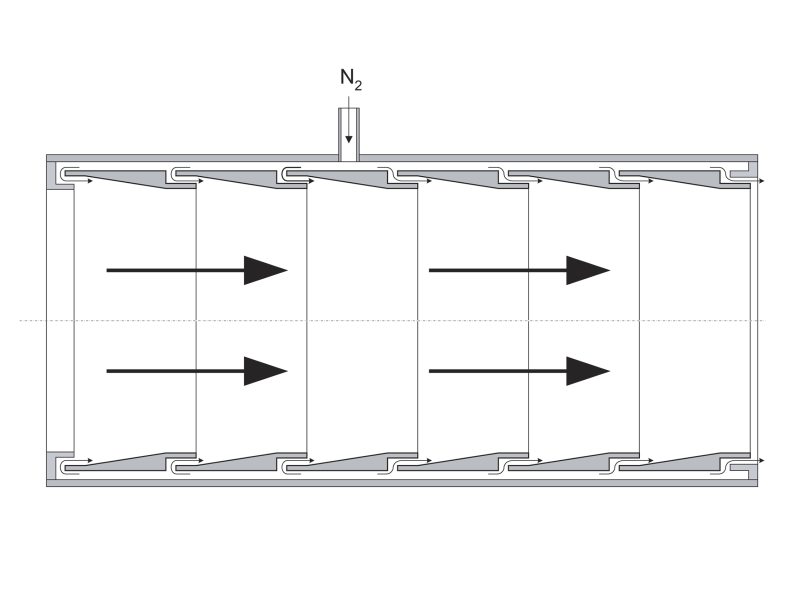

The unique Virtual Wall™ is a patented device that provides a nitrogen boundary layer inside vacuum lines. When used as part of an Effluent Management Subsystem in the vacuum foreline, the results can include increased uptime, reduced particles, increased throughput and higher yields. When used as part of a Scrubber Inlet Transition Kit in the exhaust line, the results can include increased uptime, reduced maintenance, safer cleaning and byproduct disposal, and improved throughput.

- Reduces surface chemical reaction, lowering the solid deposition at the scrubber inlet

- Prevents exposure to potentially hazardous chemicals

- Moves solid byproducts downstream into the scrubber

- Available in several sizes for use with the most common scrubber

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

VirtualWall Virtual Wall, Nitrogen Barrier Device, Effluent Management |

|

Features

Reducing Clogging at the Scrubber Inlet

The Virtual Wall, when used as one element of an Effluent Management Subsystem™, has proven very effective in reducing clogging at the scrubber inlet. The Virtual Wall at the scrubber inlet combats byproducts by:

- Preventing the chemical reaction of the byproducts in the tubing by significantly reducing water adsorption on the tube surface

- Sweeping the solid byproducts downstream into the scrubber

It should be noted that the design of the Virtual Wall for the scrubber inlets is different than that for the furnace exit.

Tailored Specifically to the Scrubber

Since the Virtual Wall is tailored specifically to the scrubber, specific dimensions are required. The Virtual Wall will be located in the entrance to the scrubber to lower deposition and clogging.

To ensure proper fit, accurate measurements must be provided. If system drawings are available, these are helpful to the design engineers. If they are not, you will need to take system measurements. For the best result, contact MKS to have an applications engineer measure the lines.

Measure each component dimension separately, starting from the scrubber. The first is the tubing internal and external diameter. Both diameters can be measured directly with a pair of calipers. Measure each subsequent component length and any ports.

Heat is often used in conjunction with the Virtual Wall to prevent initial sublimation or to minimize water adsorption on the tube.

Resources

Literature

- Virtual Wall nitrogen barrier device for LPCVD TEOS Datasheet (278.9 kB, PDF)

- Virtual Wall Nitrogen Barrier for Scrubber Inlets Datasheet (336.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity