905 MicroPirani™ Vacuum Pressure Transducer Kit

Overview

The 905 MicroPirani™ Vacuum Sensor Kit is an ultra-compact wide range vacuum transducer designed for OEM system integration. The transducer is based on well proven thermal conductivity MEMS (Micro-Electron Mechanical Systems) sensor technology and meets the demand for integrated vacuum measurement solutions.

- Wide measurement range from atmosphere to 10-5 Torr

- Three open collector set points for advanced process control

- User-friendly digital control via host processor or computer

- Robust solid state sensor is resistant to vibrations and g-forces

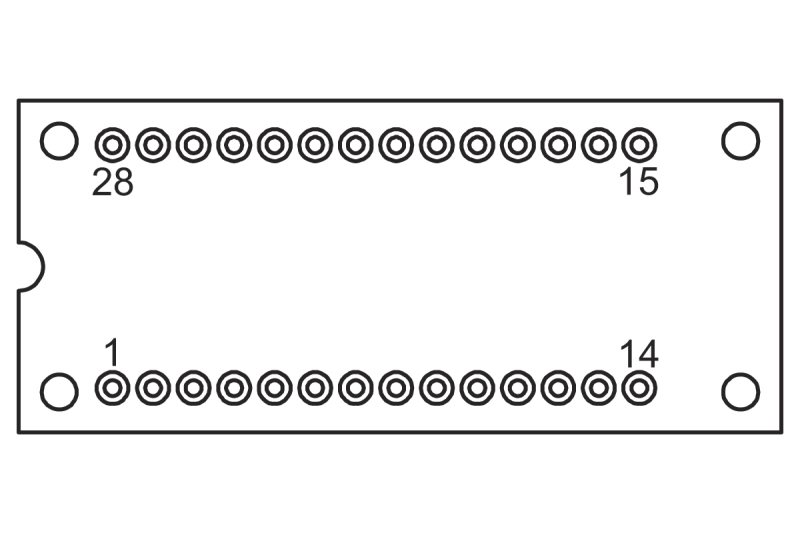

- Standard DIP 28 pin footprint for easy integration

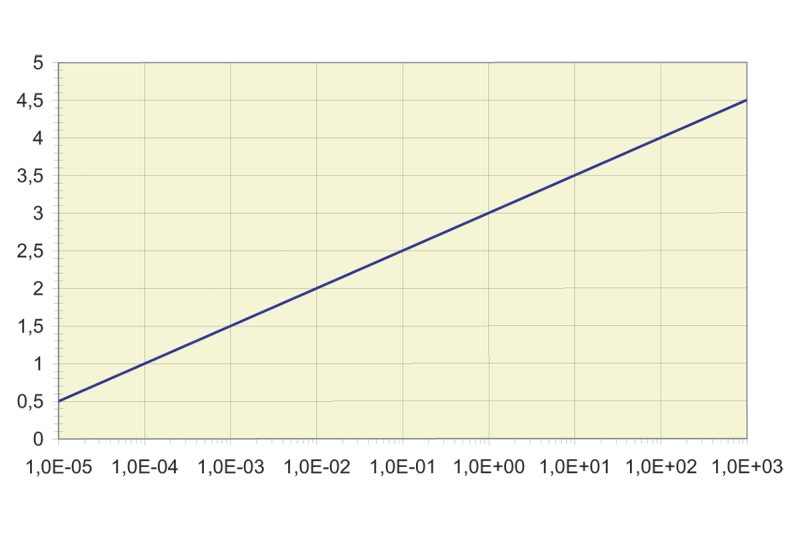

- Analog output 0.5 VDC per decade

Products

Specifications

-

Digital CommunicationSerial UART, TTL level

-

Measurement Range1 x 10-5 to 760 Torr

1 x 10-5 to 1000 mbar

1 x 10-3 to 1 × 10+5 Pascal -

Operating Temperature5° to 40°C (41° to 104°F)

-

Maximum Bakeout Temperature130°C (266°F)

-

Storage Temperature-10° to 55°C (14° to 131°F)

-

Analog Output0.5 VDC - 4.5 VDC

-

Power Requirements+5 VDC (±2%), 45 mA

-

MicroPirani Accuracy5% (typical measuring accuracy from 1E-3 to 100 Torr Nitrogen pressure measured at 25°C)

-

Exposed MaterialsSilicon, SiO2, SiN4, Epoxy, Gold

-

Weight9 grams (Electronics Module)

-

Set Point Configuration3 open collector outputs, 50 mA sink current

-

UnitsTorr, mbar, Pascal

Features

Designed for OEM System Integration

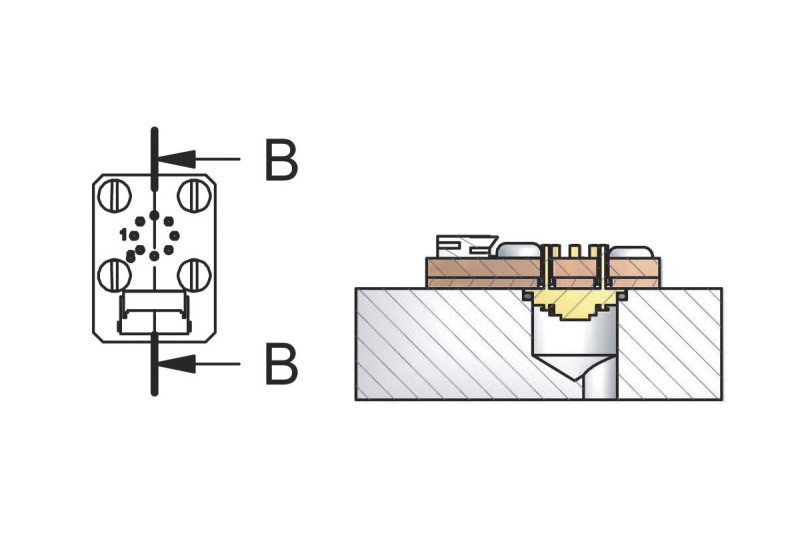

The 905 MicroPirani Sensor Kit is a calibrated plug and play vacuum pressure transducer solution for OEM system integration. The kit consists of a MEMS-based pressure sensor and a measuring electronics and processor module. The sensor module can easily be integrated into equipment vacuum systems or manifolds and occupies minimal space. The sensor is designed for o-ring sealing when connected to a 7.6 mm orifice.

Serial Communication

The TTL level UART serial interface (universal asynchronous receiver/transmitter) enables digital communication with external UART serial devices. The interface can be used for real time pressure reading and for setup and configuration of digital parameters directly from external host microprocessor.

MicroPirani™ Sensor Element

The MicroPirani sensor element consists of a silicon chip construction, where thermal conductivity is measured in a small cavity where gas is passed by diffusion instead of flow. The MicroPirani offers a wide measuring range of 1-2 decades lower than traditional wire based pirani and convection gauges. The sensor can be mounted in any orientation without compromise of measurement performance.

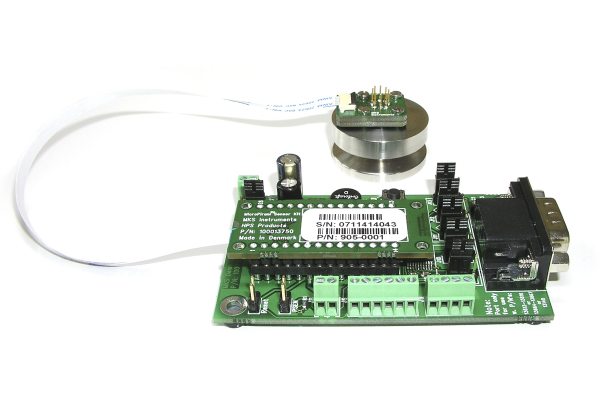

Evaluation Board

The MicroPirani Sensor Kit is designed for a high level of integration, but the evaluation board can get the MicroPirani Sensor Kit up and running in minutes. The evaluation board is supplied with a sensor element mounted on a KF16 test flange for easy vacuum connection. The evaluation board offers both RS232 and RS485 digital communication and can be connected directly to a PC for real time pressure data logging and setup of digital parameters. For easy connectivity, all Sensor Kit I/O pins are available through screw terminals at the evaluation board. The evaluation board is also compatible with the PDR900 controller that can be used for pressure readout and setup of digital parameters.

Standard DIP 28-pin Footprint

The electronics module fits a standard 28 pin DIP socket and can easily be integrated on a printed circuit board together with other electronics. The sensor module can either be wired through the circuit board or connected by a special flat cable from the electronics module.

Applications

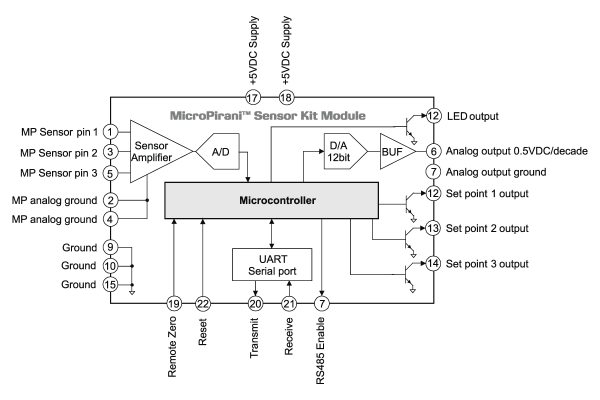

Functional Block Diagram

The 905 MicroPirani Sensor Kit can be used in a variety of applications and systems, including:

Mass Spectrometers

In a mass spectrometer, the mean distance between molecules must reach a certain distance before activating the analyzing cell. The MicroPirani Sensor Kit can be used to measure pressure and thereby determine adequate mean free path of molecules. The size of mass spectrometers is constantly shrinking and the Sensor Kit significantly reduces space taken by traditional vacuum gauges, allowing more compact equipment design.

Pumping Systems

Traditional vacuum gauges occupy significant space in pumping systems. The compact size of the Sensor Kit allows pump manufacturers to integrate vacuum measurement solutions in pumping systems like multi-stage turbo molecular pumping systems.

Space Flight Systems

The low weight and highly robust MEMS sensor design allows use in demanding application and extreme environments like equipment for use in space flight. The electronics and sensor element is designed to withstand extreme g-forces and intense vibrations experienced during rocket launch.

Resources

Manuals

- 900 Series Vacuum Transducer USB Adapter Manual (129.6 kB, PDF)

- 905 MicroPirani™ Sensor Kit, RS232/RS485 Design Guide (623.6 kB, PDF)

- 905 Vacuum Sensor Kit Board Pin-outs (42.9 kB, PDF)

- 905 MicroPirani™ Sensor Kit Functional Block Diagram (59.5 kB, PDF)

Literature

- 905 MicroPirani™ Sensor Kit (328.9 kB, PDF)

Other

- 905 RoHS Certificate of Compliance (374 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity