General Purpose Downstream Pressure Controller with Mass Flow Meter

Overview

- Percent of set point accuracy enables precise process control

- Temperature compensated pressure sensor maintains tight accuracy

- DeviceNet™, EtherCAT®, or RS485 communications

- 10µ inch electropolished 316L surface finish and metal seals for high purity applications

- Embedded user interface

- Patented mass flow sensor provides exceptional long-term accuracy and zero stability

Products

Configuration Options

The following options are available for GPCMA General Purpose Pressure Controllers with Mass Flow Meter

Ordering Code Example: GPCMA13T07103R83T110

| Configuration Option | Option Code |

|---|---|

|

GPCMA Pressure Controller with MFM |

GPCMA |

Pressure Range Full Scale |

|

| 500 Torr | 52T |

| 1000 Torr | 13T |

| 2000 Torr | 23T |

| 60 psia | 61P |

| 100 psia | 12P |

| 1000 mBar | 13M |

| 2000 mBar | 23M |

| 5000 mBar | 53M |

| 100 kPa | 12K |

| 200 kPa | 22K |

| 600 kPa | 62K |

Gas |

|

| Helium (001) | 01 |

| Argon (004) | 04 |

| Hydrogen (007) | 07 |

| Nitrogen (013) | 13 |

Full Scale Flow Rate |

|

| 5 sccm | 500 |

| 10 sccm | 101 |

| 20 sccm | 201 |

| 50 sccm | 501 |

| 100 sccm | 102 |

| 200 sccm | 202 |

| 500 sccm | 502 |

| 1000 sccm | 103 |

| 2000 sccm | 203 |

| 5000 sccm | 503 |

| 10000 sccm | 104 |

| 20000 sccm | 204 |

| 30000 sccm | 304 |

| 50000 sccm | 504 |

Fittings |

|

| Swagelok 4 VCR | R |

| ¼ in. Swagelok | S |

| C-Seal | C |

| W-seal (1.125 in.) | H |

Communications |

|

| DeviceNet | 6 |

| EtherCAT | 8 |

| RS485 (ASCII) | 5 |

Orifice Size |

|

| A (50 sccm) | A |

| #1 (200 sccm) | 1 |

| #2 (1000 sccm) | 2 |

| #3 (5000 sccm) | 3 |

| #4 (10,000 sccm) | 4 |

| #5 (20,000 sccm) | 5 |

| #6 (30,000 sccm) | 6 |

| #7 (50,000 sccm) | 7 |

Plug Material |

|

| Teflon | T |

Valve Type |

|

| Normally Closed | 1 |

Firmware |

|

| Customer must specify firmware version at time of order | 10 |

Specifications

-

TypeGPCMA Absolute Pressure Controller with Mass Flow Meter

-

Pressure Range500 Torr, 1000 Torr, 2000 Torr, 100 psia Full Scale

-

Fitting TypeSwagelok® 4 VCR Male

1-1/8 inch surface mount (C-seal, W-seal)

1/4 inch Swagelok compression seal -

Valve PositionNormally Closed

-

Valve SeatPTFE (Teflon®)

-

Flow Rate5, 10, 20, 50, 100, 200, 500, 1000, 2000, 5000, 10000, 20000, 30000, 50000 (N2 equivalent)

-

Pressure Readout UnitsTorr, kPa, psi, mbar

-

Pressure Resolution0.1 Torr

-

Pressure Control Accuracy±1.0% of Reading >20% Full Scale

±0.2% of Full Scale <20% of Full Scale Flow (including non-linearity, hysteresis, and non-repeatability referenced to 760 mmHg and 0°C) -

Transducer Over Pressure Limit2x Full Scale for all ranges

-

Maximum Differential Pressure45 psid

-

Burst Pressure1500 psig

-

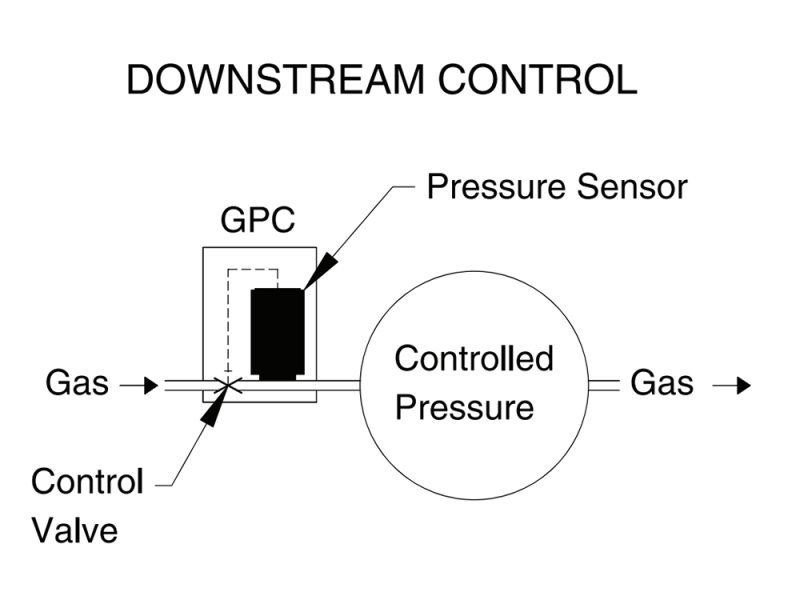

Control ModeDownstream

-

Pressure Measurement Accuracy±0.5% of Reading

-

Zero Temperature Coefficient±0.02% of Full Scale/°C

-

Span Temperature Coefficient±0.04% of Reading/°C

-

Control Range>2 to 100% of Full Scale

-

Typical Response Time<1.0 second

-

Operating Temperature10-50°C (50-to 122°F)

-

Storage Temperature-20-80°C (-4-176°F)

-

Storage Humidity0 to 95% Relative Humidity, non-condensing

-

External Leak Integrity<1 x 10-10 (scc/sec He)

-

Leak Integrity Through Closed Valve<1.0% of orifice Full Scale (Nitrogen at 25 psig on inlet to atmosphere)

-

Flow Measurement Range2% to 100% of Full Scale

-

Flow Repeatability±0.3% of Reading

-

Flow Resolution0.1% of Full Scale

-

Flow Accuracy±1.0% of Reading >20% of Full Scale

±0.2% of Full Scale (>20% of Full Scale flow)

(including non-linearity, hysteresis, and non-repeatability referenced to 760 mmHg and 0°C) -

Flow Span Temperature Coefficient<0.08% of Reading/°C

-

Flow Zero Temperature Coefficient<0.05% of Full Scale/°C

-

Wetted MaterialsStandard: 316L S.S. VAR (equivalent to 316 S.S. SCQ for semiconductor quality), 316 S.S., Elgiloy®, KM-45

Optional: PTFE (Teflon) Valve Seat -

Surface Finish<10 µinches, average Ra electropolished

-

Power RequiredDeviceNet™: +11 to +25 VDC per (<4 watts)

EtherCAT®: +24 VDC (<5 watts)

RS485: +15 to +24 VDC(<4 watts) -

Connector-InterfaceDeviceNet™: 5 pin micro connector (power and comm.)

EtherCAT®: 2 x RJ-45 (comm.) male, M8 male, 5 pin (power)

RS485: 9 pin Type D male (power and comm.) -

Data Rate SwitchDeviceNet™: 4 positions: 125, 250, 500K (Default), (programmable over network)

EtherCAT®: No switch

RS485: No switch (set data rate via RS485) -

EtherCAT Communication Rate100 Mbps

-

DeviceNet Communication Rate125 Kbps, 250 Kbps, 500 Kbps

-

RS485CommunicationRate9.6 Kbps,19.2 Kbps,38.4 Kbps

-

MAC ID SwitchesDeviceNet™: 2 switches, 10 positions: 0,0 to 6,3, 1 to 254

EtherCAT®: 3 switches, 16 positions

RS485: Set address over RS485, Station Addresses 0,0 to 9,9 -

Network SizeDeviceNet™: Up to 64 nodes

EtherCAT®: Up to 4095 nodes

RS485: Up to 32 nodes -

IndicatorsDeviceNet™: LED Network (green/red), LED Module (green/red)

EtherCAT®: LED Power (green), LED Run (green), LED Error (red), LED Comm (green)

RS485: LED Comm (yellow),LED Error (red) -

Weight<3 lbs (1.36 kg)

-

ComplianceCE

Features

Digital I/O

The GPCMA digitally controlled pressure controller is available with digital I/O (EtherCAT®, DeviceNet™ or RS485). The digital control electronics utilize the latest in MKS control algorithms providing fast and repeatable response to set point throughout the device control range. Typical response times are less than 1 second dependent on installation conditions. Included is a digital calibration that yields 1% of set point accuracy.

High Purity Applications

The GPCMA, with 4 VCR® fittings, is 1.125'' (28.6 mm) wide and 4.88'' (124 mm overall) length allowing it to fit in standard gas systems. It is also available with the 1.125'' (38.6 mm) IGS compatible c-seal and w-seal configurations. The GPCMA metal-sealed, pressure controller with its 10 microinch, electropolished surface finish is well suited for use in high purity process applications. The GPCMA is available with a normally closed valve.

Resources

Drawings & CADs

- GPCA/GPCMA Mass Flow Controller Dimensional Drawings (429.9 kB, PDF)

- GPCMA Pressure Controller 3D Model Files

Literature

- GPCMA General Purpose Pressure Controller with Mass Flow Meter (535.2 kB, PDF)

Manuals

- G-Series Pressure Controller Manual (1.9 MB, PDF)

- GPCA/GPCMA Pressure Controller Pin-outs (22.2 kB, PDF)

Device Description Files

- MKS GPCMA ESI File (231.8 kB, XML)

- MKS GPCMA EDS File (353.7 kB, EDS)

Ultra-High Velocity

Ultra-High Velocity