Cirrus™ 3-XD High Sensitivity Atmospheric Systems with V-lens™ Technology

Overview

Designed for researchers and engineers who need to work beyond the limits of conventional quadrupole MS technology, the CirrusTM 3-XD system delivers a unique analytical advantage for eXtreme Detection. The proven Cirrus Quadrupole MS platform utilizes patented-V-lens™ ion optics with a double-focussing and deflection capability to produce a consistently low baseline for any gas species for trace level detection with greater clarity and confidence than ever before. With its versatile, compact design and powerful, automatable software control, the Cirrus 3-XD system provides a new level in performance, robustness, and ease of use for the most challenging trace gas analyses.

- Gas-independent low baseline with robust detection to low ppb levels

- Detection of concentrations from trace levels (low ppb) to high abundance

- Unique oven design offers stable and reliable temperature performance

- Automated variable pressure inlet enables accurate profiling of pure gases and gas mixtures

- Convenient benchtop and rack-mount configurations

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

CIRRUS-3-XD Atmospheric Gas Analyzer, Quadrupole Mass Spectrometry, Cirrus 3-XD, V-lens |

|

Specifications

-

Mass Range1 to 100, 100HP, 200 or 300 amu options

-

Minimum Detectable ConcentrationGas & Mass Independent

minimum detectable concentration 3 sigma baseline noise is <15 ppb -

Electron Energy & Emission CurrentOperator variable

-

Operating Temperature5° to 35°C

-

Maximum Operating Conditions20% to 80% RH (non-condensing)

-

Bake Out Temperature180°C

-

Inlet2.0 m long with 1/4 inch Swagelok® end connection, heated to 150°C

-

Gas Consumption20 ml/min

-

Sample Pressure1 bar nominal

-

Pumping SystemHigh compression turbo-molecular pump with internal 4-stage diaphragm backing pump standard, corrosive gas pumping with all internal pumps optional

-

Automated Inlet Pressure ControllerA 640 (Baratron® capacitance manometer based) automated inlet pressure controller is available as an option

-

PC RequirementsMicrosoft® 32 bit or 64 bit Windows® 7 or 10

-

Interfaces1 x LAN port required

-

I/O Capability4 analog inputs (-11 to +11 volt, 22 bit)

2 analog outputs (0-10 volt, 12 bit)

16 TTL digital I/O -

Power Requirements100-240 VAC/50-60 Hz

-

ComplianceCE

Features

V-lens™ Technology

V-lens ion-optics technology uses a unique, patented double-focussing and deflection mechanism to significantly reduce background and enhance sensitivity. The result is an atmospheric pressure gas analyzer with low limits of detection (typically in the mid to low ppb range) without compromise to any other aspect of instrument performance - even when working with the most challenging gases that can produce large amounts of chemical background noise via metastable decay. This novel technological design provides significant improvements in quality and clarity in the data obtained, for any application where detecting the lowest levels of contamination with confidence is important.

Heating and Vacuum System

The Cirrus 3-XD features a number of advancements in design that aid stability and reproducibility of results. The vacuum chamber (with quadrupole analyzer) and inlet interface assembly is housed within a precision engineered stainless steel oven, providing low heat sink characteristics. This offers high temperature uniformity and eliminates potential cold spots that could otherwise cause undesirable sample condensation and variance in analyses. The oven design enables user-defined temperature control of the oven and capillary, allowing for finer analytical control.

The quadrupole analyzer itself is contained within a stainless steel vacuum chamber which is pumped by a high compression turbo molecular/diaphragm pump combination. The vacuum system is backed by an internal 4-stage diaphragm pump to maintain the integrity of the compact design. The entire Cirrus 3-XD vacuum chamber can also be baked to reduce residual gas background species and to minimize any memory effects.

Gas Inlet

An essential feature of any gas analyzer is the ability to not contaminate or alter the gas sample in any way. The Cirrus 3-XD inlet assembly incorporates either fused silica or stainless steel capillaries that can be heated to a stable user-defined temperature. The inlet assembly allows for easy replacement of capillaries, while the optimized insulation maximizes stability and reduces heat radiation.

The low volume and surface area of the assembly serves to maximize response speed while minimizing memory effects. Cirrus 3-XD systems can also be configured with inlets for multi-stream sampling, stainless steel capillaries for resistance to fluorine-based compounds, and a pressure controller inlet (incorporating a gas independent capacitance manometer) to allow sampling from sources that vary from the nominal 1 bar inlet requirement. The Cirrus 3-XD vacuum system utilizes a high compression turbo molecular pump, so light gases such as hydrogen and helium can be sampled with no additional expensive pumping requirements.

Maintenance and Access

The Cirrus 3-XD internal oven has a removable cover allowing easy access to the inlet interface, vacuum chamber and analyzer ion source. This is particularly helpful for routine maintenance like filament and capillary replacement. A hot cathode ion gauge is incorporated for independent vacuum pressure measurement and to provide an interlock signal for protection of the mass spectrometer. A temperature sensor also ensures that the electron multiplier detector cannot be switched on at high temperatures. The Cirrus 3-XD is designed with a lubricantfree pumping system and no elastomer seals are used in the sample inlet system or in the high vacuum region of the system.

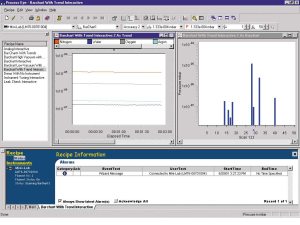

Process Eye™ Professional Software

Cirrus 3-XD is operated using proven Process Eye Professional software, a recipe-driven platform that communicates with the system over a TCP/IP network. Process Eye Professional is designed for use with the latest Microsoft® operating systems including 32 bit or 64 bit Windows 7 and 10. Features and Benefits include:

- Data presented in units relevant to the application

- Fully automated operation and calibration

- New workflow ''Recipes'' for quantitative applications

- User-configurable alarms and warnings

- Can be configured to track data from other process sensors (temperature, pressure, flow, etc.)

Applications

- Monitoring trace contaminants to low ppb, in process gases of all types

- Gas purity and manufacturing QC

- Catalysis studies including chemisorption

- Fuel cell monitoring and development

- Environmental monitoring

- Thermal analysis - TGA, DTA

- Fermentation process monitoring

- Heat treatment/furnace monitoring

- Membrane studies

- Glove box gas monitoring

- Lamp manufacture

- Freon detection and identification

Ultra-High Velocity

Ultra-High Velocity