390 Micro-Ion® ATM Modular Vacuum Pressure Transducers

Overview

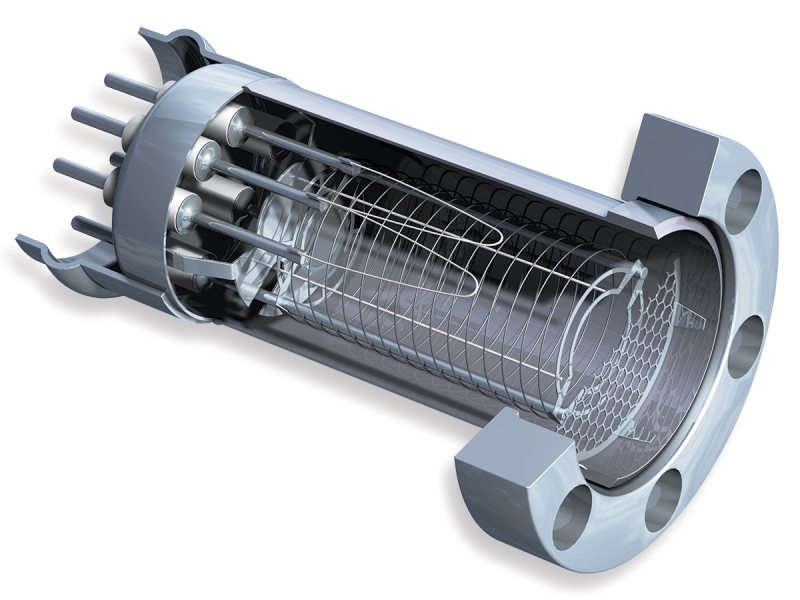

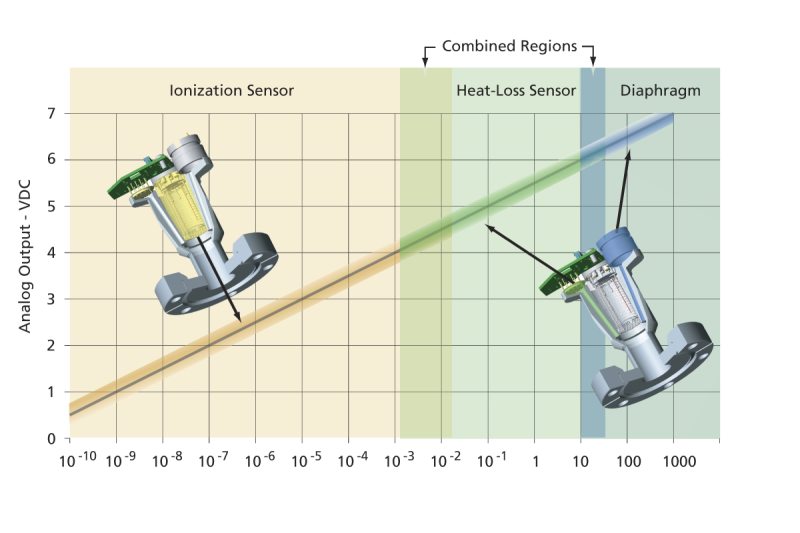

The Granville-Phillips® 390 Micro-Ion® module combines proven Micro-Ion ionization gauge technology with a miniature Conductron heat loss sensor and two Piezo resistive sensors to provide accurate, continuous pressure measurement from high vacuum to atmosphere. Using its diaphragm sensors, this product is capable of providing accurate absolute pressure up to atmosphere along with precise indication of vacuum chamber differential pressure from ambient.

- Continuous pressure measurement from 10-9 Torr to atmosphere

- Precision differential pressure measurement at atmosphere

- Dual ionization gauge filaments increase equipment uptime

- Optional set point relays for process control

- Analog, RS-485, DeviceNet or EtherCAT interfaces

- Optional graphical LCD display

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

390410-0-YG-T Vacuum Gauge, Micro-Ion ATM, 2.75 in. CF, Analog |

15 Weeks

|

$1,462 |

|

|||

|

390411-0-YE-T Vacuum Gauge, Micro-Ion ATM, Display, NW25 ISO-KF, Analog |

|

$1,683 |

|

|||

|

390511-2-YE-T Vacuum Gauge, Micro-Ion ATM, Display, NW25-KF, RS485, 2 Relays |

15 Weeks

|

$1,930 |

|

|||

|

390511-2-YG-T Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF, RS485, 2 Relays |

|

$1,985 |

|

|||

|

390511-3-YE-T Vacuum Gauge, Micro-Ion ATM, Display, NW25 ISO-KF, RS-485, Analog | $1,985 |

|

||||

|

Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF Flange, RS-485, Analog

$2,013

|

390511-3-YG-T Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF Flange, RS-485, Analog |

|

$2,013 |

|

||

|

Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF, DeviceNet, 2 Relays

$1,875

|

390610-2-YG-T Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF, DeviceNet, 2 Relays | $1,875 |

|

|||

|

Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF, DeviceNet, 3 Relays

$2,151

|

390611-3-YG-T Vacuum Gauge, Micro-Ion ATM, Display, 2.75 in. CF, DeviceNet, 3 Relays | $2,151 |

|

|||

|

390710-2-YE-T Vacuum Gauge, Micro-Ion ATM, NW25-KF, EtherCAT, 2 Relays |

15 Weeks

|

$1,785 |

|

|||

|

390710-2-YG-T Vacuum Gauge, Micro-Ion ATM, 2.75 in. CF, EtherCAT, 2 Relays |

15 Weeks

|

$1,838 |

|

Configuration Options

The following options are available for 390 Micro-Ion® Vacuum Pressure Transducers

Ordering Code Example: 390410-2-YG-T

| Configuration Option | Option Code |

|---|---|

Micro-Ion ATM Module |

|

| RS-485/Analog | 390510 |

| RS-485/Analog with digital display | 390511 |

| DeviceNet | 390610 |

| DeviceNet with digital display | 390611 |

| EtherCAT | 390710 |

Set Point Relays |

|

| Two (EtherCAT is only available with 2 set point relays) | 2 |

| Three | 3 |

Ionization Gauge Filament Types |

|

| Yttria-coated iridium filaments | Y |

| Tungsten | T |

Vacuum Connections |

|

| NW16-KF | D |

| NW25-KF | E |

| NW40-KF | K |

| 1.33 in. (NW16-CF) ConFlat-type | F |

| 2.75 in. (NW35-CF) ConFlat-type | G |

| 0.5 in. VCR-type Male | H |

Measurement Units |

|

| Torr | T |

| mbar | M |

| Pascal | P |

The following options are available for 390 Micro-Ion® Replacement Sensors

Ordering Code Example: 390100-Y-E

| Configuration Option | Option Code |

|---|---|

Micro-Ion ATM Module |

|

| Replacement gauge | 390100 |

Ionization Gauge Filament Types |

|

| Yttria-coated iridium | Y |

| Tungsten | T |

Vacuum Connections |

|

| NW16-KF | D |

| NW25-KF | E |

| NW40-KF | K |

| 1.33 in. (NW16-CF) ConFlat-type | F |

| 2.75 in. (NW35-CF) ConFlat-type | G |

| 0.5 in. VCR-type Male | H |

Specifications

-

Absolute Measurement Range1 x 10-9 Torr to atmosphere

1.33 x 10-9 mbar to atmosphere

1.33 x 10-7 Pascal to atmosphere

(air or N2) -

Differential Measurement Range-750 to +250 Torr

-999 to +188 mbar

-99.9 to 18.8 kPascal -

Typevacuum transducer

-

SensorIonization gauge

-

DisplayGraphics LCD (optional)

-

Operating Temperature10° to 40°C (50° to 104°F)

-

Maximum Bakeout Temperature105°C (221°F) maximum, with electronics removed

-

Storage Temperature-40° to +70°C (-40° to +158°F)

-

Analog OutputAbsolute: Logarithmic, 0.5 to 7.0 VDC, 0.5 V per decade

Differential: Linear 1-5 VDC, -750 to +250 Torr

-

Internal Volume10.8 cc

-

Exposed Materials304 stainless steel, tantalum, tungsten, yttria-coated iridium, alumina, CuAg eutectic, Kovar, gold or nickel plated Kovar, borosilicate glass

-

Electronic Casing and FlangeAluminum Extrusion with Powder-coat

-

Weight728.5 gm (25.7 oz) - 2.75 ConFlat fitting)

-

ComplianceCE

-

Span Temperature Coefficient-10

-

X-ray Limit3 x 10-10 Torr

4 x 10-10 mbar

4 x 10-8 Pascal -

LED IndicatorModule status

Features

Unique Sensor Design

Traditionally, accurate measurement across a wide vacuum range required multiple sensors, multiple vacuum system ports, associated cables and electronics. The unique Micro-Ion® ATM sensor design eliminates thermal effects that can influence the performance of the heat loss sensor at higher pressures. The Micro-Ion ATM module combines multiple sensors in one microprocessor-based design, reducing overall cost of ownership, while enhancing vacuum measurement performance.

Analog Output and Digital Interface

The full range pressure measurement is output as a single analog signal or available through optional serial RS-485, DeviceNet™ or EtherCAT™ digital interfaces. The RS-485 interface allows for communications between the module and host controller, and for module configuration. The DeviceNet interface provides high speed access to pressure measurement and easy configuration of gauge parameters. The EtherCAT interface provides "processing on the fly" principal, with minimizing processing delays. The RS-485, DeviceNet and EtherCAT versions have up to three optional set point relays that can be configured for process control, with the ability to assign the relays at any pressure across the vacuum pressure range or to a specific differential pressure value.

Compact Design

One Micro-Ion gauge, a heat-loss sensor with a barometric diaphragm sensor, an absolute pressure diaphragm, and control electronics are all housed in a compact, modular package.

Field-Replaceable Gauge Assembly

The vacuum gauge assembly can be quickly and easily replaced in the field using only a screwdriver after removal from the vacuum system.

Resources

Literature

- Vacuum Measurement Product Guide (711.5 kB, PDF)

- 390 Micro-Ion® ATM Modules (470.8 kB, PDF)

Manuals

- 390, 392 Vacuum Transducer Pinouts (219.2 kB, PDF)

- 390 Micro-Ion® ATM Module Instruction Manual 390412-X-XX-X (80.5 kB, PDF)

- 390 Micro-Ion® ATM Four-Sensor Combination Vacuum Gauge ModuleManual (1.1 MB, PDF)

- 390 Micro-Ion® ATM Gauge Removal and Replacement Procedure (162.5 kB, PDF)

- 390 Micro-Ion® Gauge with Filament Status Output Manual Addendum (111.5 kB, PDF)

- 390 Micro-Ion® ATM Four-Sensor Combination Vacum Gauge ModuleManual (1.3 MB, PDF)

- 390 Micro-Ion® ATM EtherCAT Manual (848.6 kB, PDF)

Other

- 390 & 392 Declaration of Conformity (373.8 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity