High Performance Pressure-insensitive, Multi-gas, Multi-range 5 sccm to 50 slm Mass Flow Controllers

Overview

- Flow rates from 5 to 50,000 sccm

- Pressure insensitive with integral pressure sensor

- Multi-gas/multi-range with 1% of set point accuracy

- Analog I/O: 0 to 5 VDC

- Digital I/O: DeviceNet, EtherCAT

Products

Configuration Options

The following options are available for P9B Pressure-insensitive Mass Flow Controllers

Ordering Code Example: P9B013502C6T030

|

Configuration Option |

Option Code |

|---|---|

| P9B Mass Flow Controller | P9B |

Gas (Per Semi Standard E52-0703) |

|

| Nitrogen (N2) | 013 |

| Ammonia (NH3) | 029 |

| Sulfur Hexafluoride (SF6) | 110 |

| Other Gas Options | See Here |

Flow Range Full Scale |

|

| 5 sccm | 500 |

| 10 sccm | 101 |

| 20 sccm | 201 |

| 50 sccm | 501 |

| 100 sccm | 102 |

| 200 sccm | 202 |

| 500 sccm | 502 |

| 1000 sccm | 103 |

| 2000 sccm | 203 |

| 5000 sccm | 503 |

| 10000 sccm | 104 |

| 20000 sccm | 204 |

| 30000 sccm | 304 |

| 50000 sccm | 504 |

Fittings (compatible with) |

|

| 4 VCR Male | R |

| C-seal (1.125 in.) | C |

| W-seal (1.125 in.) | H |

| W-seal (1.5 in.) | F |

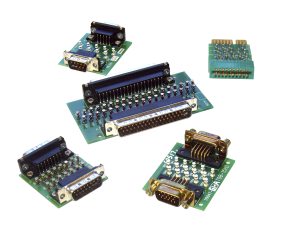

Connector |

|

| EtherCAT | 8 |

| DeviceNet | 6 |

| 9 pin D connector | A |

| 15 pin D connector | B |

Valve Type |

|

| Normally Closed, Teflon® (10 sccm - 50 slm) | T |

Reserved |

|

| Standard | 0 |

Firmware |

|

| EtherCAT | 10 |

| All Other I/O | 30 |

Specifications

-

Full Scale Flow Range5-50,000 sccm (N2 equivalent)

-

Maximum Inlet Pressure150 psig

-

Normal Operating Pressure Differential10-5000 sccm; 10-40 psid

10000-20000 sccm; 15-40 psid

10000-20000 sccm; 15-40 psid

(N2 Full Scale with atmospheric pressure at the MFC outlet) -

Proof Pressure1000 psig

-

Burst Pressure1500 psig

-

Control Range2% to 100% of Full Scale

-

Typical Accuracy±1% of set point for 20-100% Full Scale

±0.2% of Full Scale for 2-20% Full Scale -

Repeatability±0.3% of Reading

-

Resolution0.1% of Full Scale

-

Zero Temperature Coefficient< 0.05% of Full Scale/°C

-

Span Temperature Coefficient< 0.08% of Reading/°C

-

Inlet Pressure Coefficient< 0.02% of Reading/psi

-

Typical Settling Time< 750 msec., typical above 5% Full Scale

-

Warm-up Time30 minutes

-

Operating Temperature10° to 50°C

-

Storage Humidity0 to 95% Relative Humidity, non-condensing

-

Storage Temperature-20° to 80°C

-

Temperature Display0 to 100°C

-

Temperature Accuracy±2°C

-

Temperature Resolution0.1°C

-

Display4 digits for value, 4 characters for unit

-

Pressure Display0 to 100 psia

-

Pressure Readout Unitspsia, kPA

-

Pressure Accuracy1% Full Scale

-

Pressure Resolution0.1 psia

-

External Leak Integrity< 1 x 10-10 (scc/sec He)

-

Leak Integrity Through Closed Valve< 1.0% of Full Scale at 25 psig inlet to atmosphere

-

Wetted Materials316L S.S. VAR, 316 S.S., Elgiloy, KM-45

-

Valve Seat MaterialPTFE (Teflon)

-

Surface Finish10µ inch average Ra

-

Weight3 lbs (1.4 kg)

-

ComplianceCE

-

Attitude Insensitivity0.25% of Full Scale for indicated zero, span and actual span

-

Pressure Transient±5% of set point from 20 to 100% of Full Scale when subject to a 2 psi inlet pressure transient

Features

MKS P Series Mass Flow Controllers

P-Series high performance MFCs feature full digital control architecture for fast response to setpoint over the operable device range. The embedded web browser application allows changes in gas type and full scale flow, which reduces overall costs by minimizing the number and variety of MFCs that must be kept in inventory.

Communications Options

| Digital I/O | DeviceNet™ | EtherCAT® |

|---|---|---|

| Input Power Required | +11 to +25 VDC per DeviceNet specification (@ <2.0 watts) | +24 VDC (<5 watts) |

| Connector | 5 pin microconnnector (DeviceNet) | 2 x RJ-45 (comm.) male, M8 male, 5 pin (power) |

| Data Rate Switch/Selection | 4 positions: 125, 250, 500K (Default), PGM (programmable over the network) | No switch |

| Data Rate/Network Length | Data rate (user selectable) 125 Kbps, 500 meters (1,640 feet) 250 Kbps, 250 meters (820 feet) 500 Kbps, 100 meters (328 feet) |

100 Mbps |

| MAC ID Switches/Addresses | 2 switches, 10 positions; 0,0 to 6,3 are hardware ID numbers 7,0 to 9,9 are software ID numbers (6,4 to 6,9 are unused and, if selected will default to hardware ID number 6.3) |

3 switches, 16 positions |

| Network Size | Up to 64 nodes | Up to 4095 nodes |

| Network Topology | Linear (trunkline/dropline) power and signal on same network cable | n/a |

| Visual Indicators | LED network status (green/red) LED module status (green/red) Scrolling LED displays (MFC Type, Flow Full Scale, Gas Type, IP address, Instance Number (1 to 31) |

LED Power (green) LED Run (green) LED Error (red) LED Comm (green) |

| Compliance | CE | CE |

Short Process Steps Performance

The performance capabilities of the P9B are quickly apparent where short process steps are required given the sub 750 millisecond control times and accuracy to within 1% of set point. This performance extends over the range of process gases, whether “light” gases such as helium or “heavy” gases like SF6. The P9B is a true multi-range/multi-gas MFC that enables the user to have confidence in this device’s capability and minimize MFC inventory requirements.

Multi-Gas / Multi-Range Capability

Utilization of the multi-gas/multi-range capability is made simple through the device’s embedded software and standard Ethernet interface that requires no special software, only a standard web browser and a PC. Already stored on the device are critical gas parameters for most of the gases in use today by the semiconductor industry. It is a simple matter of selecting the gas and specifying the range to configure the device. Through this interface the user can also perform device monitoring diagnostics while the device is operating.

Resources

Literature

- P9B Pressure Insensitive, Mass Flow Controller, 5-50,000 sccm (283.4 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity