Configuring MKS 640/641 Pressure Controllers

Valve Orifice:

Full Scale ranges of 10, 100, or 1000 Torr are available. Each 640 or 641 can control pressure from Full Scale to less than 2% of Full Scale. Prudent design suggests choosing the lowest possible Full Scale for the application, taking into consideration the overpressure to which the sensor may be exposed (both normal and accidental).

Valve Orifice:

Please Note: This procedure is provided as a reference guide to sizing the orifice for most typical applications. To assure proper orifice size selection for the specific application conditions, particularly those where the procedure results in an orifice selection near the limit lines in the graph, please contact MKS Applications Engineers for assistance in selecting the proper valve orifice.

The flow through any orifice depends on the size of the orifice, the inlet and outlet pressures, and gas density. To simplify 640/641 orifice selection, use the following procedure:

-

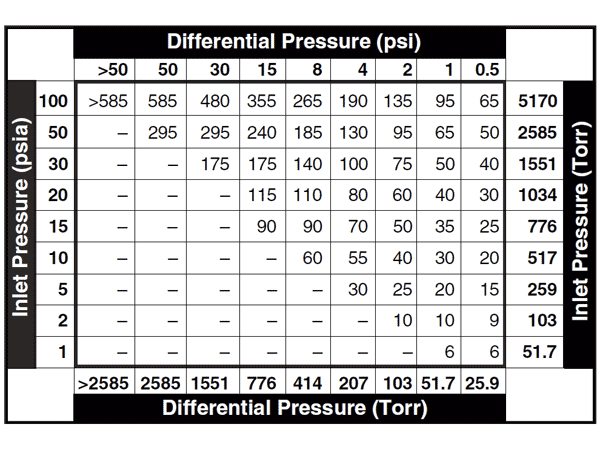

On the Index Number Table in Figure 1, choose your inlet pressure from the column of pressures on the left - the pressure that will be applied to the inlet of your 640/641. (Note that the values are absolute pressure.)

Figure 1 - Index Number Table

Figure 1 - Index Number Table - Next, from the row of pressures at the top of that table, select your differential (delta) pressure - this is the inlet pressure minus your outlet pressure.

- Locate the Index Number - where your selected row and column intersect.

-

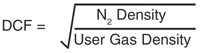

If you are using N2, skip to step #6. For other gases, calculate the Density Correction Factor (DCF) by the following formula:

- Multiply this Density Correction Factor times the Index Number found in step 3, to determine your density-corrected Index Number.

-

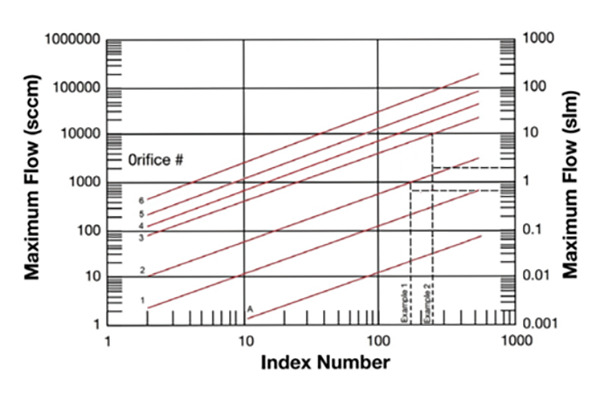

Go to the Orifice Selection Graph (Figure 2) and locate your Index Number along the bottom axis.

Figure 2 - Orifice Selection Graph

Figure 2 - Orifice Selection Graph - Draw a vertical line at your Index Number. This line will intersect with the Maximum Flow Rate lines for the valve orifices available.

- Choose the orifice whose maximum flow rate exceeds your requirements. If the point on the graph falls close to the maximum flow rate for an orifice, you may choose the next largest orifice number. Note: The above procedure is a useful tool for most typical configurations and applications. If your particular pressure control application falls outside these parameters, please contact our Applications Engineers for assistance in selecting the proper valve orifice.

Pressure Range:

In the Type 640 Controller, the Baratron pressure transducer measures absolute pressure; in the Type 641 model, it measures gauge pressure (pressure relative to ambient barometric pressure). In both models, Full Scale ranges of 10, 100, or 1000 Torr, or 60 or 100 psi are available. Each 640/641 can control pressure from Full Scale to less than 2% of Full Scale. Prudent design suggests choosing the lowest possible Full Scale for the application, taking into consideration the overpressure to which the sensor may be exposed (both normal and accidental).

Example 1

You want to control your process pressure at 5 psia, with a flow rate of 750 sccm of N2. Your inlet pressure is 15 psig (30 psia) giving a differential pressure (delta P) of 25 psi. Your delta P of 25 psi gives an Index Number value of 175. Drawing a vertical line on the Orifice Selection Chart at 175 indicates Orifice #2 would be the best choice.

Example 2

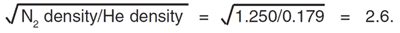

You want to control a vacuum process at a pressure of 0.5 psia, with a flow rate of 2000 sccm of He. Your inlet pressure is 15 psia, giving a differential pressure (delta P) of 15 psi, resulting in an uncorrected Index Number value of 90. The gas density correction for He is calculated as:

Multiplying 2.6 by 90 gives a density-corrected Index Number of 234. Drawing a vertical line on the Orifice Selection Chart at 234 indicates Orifice #3 would be the best choice.

This information subject to change without notice.

Learn more about 640B Integrated Absolute Pressure Controllers here

Learn more about 641B Integrated Gauge Pressure Controllers here

Ultra-High Velocity

Ultra-High Velocity