ILP Integrated Soft-start Vacuum Isolation Valve

Overview

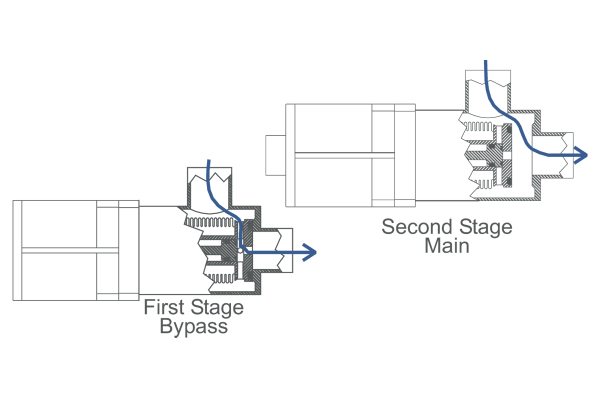

Integrated LoPro™ (ILP) valves are pneumatically actuated isolation valves with a bypass valve integrated internally to the main valve. The main valve is a normally closed bellows sealed valve. The bypass valve is a normally closed O-ring shaft sealed valve located within the main stage. In the first stage, the bypass valve pumps down slowly from atmospheric pressure to a preset vacuum pressure. In the second stage, the main valve opens, allowing use of full pumping speed.

- NW25 - NW50

- Compact design with two valves in one compact body

- 1,000,000 cycles (clean environments)

- The bypass stage conductance is adjustable by turning an adjustment screw

Products

Configuration Options

Please see the ILP Low-profile Valve datasheet for available product options.

Specifications

-

TypeLow-profile, Integrated Two Stage, Soft-start Isolation Valve

-

Vacuum RangeAtmosphere to 1.0 x 10-9 Torr

-

Body ConfigurationAngle, Inline

-

Port SizeNW25, NW40, NW50

-

Helium Leak Rate1.0 x 10-9 std cc/sec

-

Limit SwitchFunction of actuation: Normally open

Operating voltage range: 12-27 VDC (24 VDC nominal)

Switching current: 1W (DC) max.

Response time: on - < 0.6 msec

Temperature range: -20 to 70°C

-

Cylinder VolumeMain: 1.2 - 6.4 in.3, depending on configuration

Bypass: 0.16 in3 -

Cylinder Air Pressure90 psig ±30 psig

-

Blow-By PressureMain: 45 - 100 psia, depending on configuration

Bypass: > 100 psia -

Actuation TimeMain: 0.12-0.45 seconds opening, 0.18 - 1.13 seconds closing, depending on configuration

Bypass: <0.10 seconds -

Typical Life1,000,000 cycles

Features

Two-Stage Valve Design

The ILP is a pneumatically-actuated poppet valve with a bypass valve combined into a single unit. The main valve is a normally closed bellows sealed valve. The bypass valve is a spring to close, o-ring sealed valve located within the main stage.

In the first stage, the bypass valve pumps down slowly from atmospheric pressure to a preset vacuum pressure. In the second stage, the main valve opens, allowing use of full pumping speed.

A formed 321 stainless steel bellows, not edge-welded, prevents outgassing, virtual leaks, and particle entrapment between bellows convolutions and extends the main valve’s cycle life. We have optimized the bellows stroke length to assure a longer cycle life while maintaining a high conductance.

Bypass Pumpdown

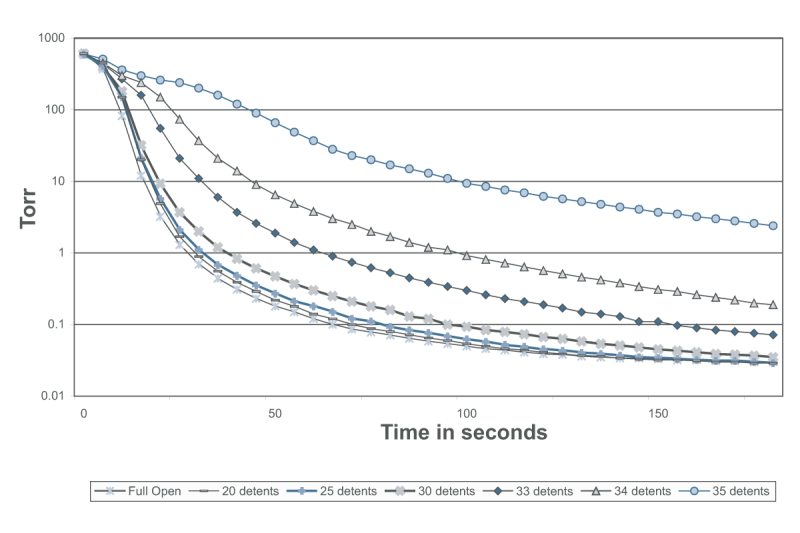

The bypass stage conductance is adjustable by turning an adjustment screw. The adjustment screw has machined detents that lock the screw into place during cycling. There are 10 detents per full turn. See Figure for the bypass pumpdown curve.

Applications

Vacuum systems often require a slow initial evacuation of the roughing or loadlock area of the system. This process is called soft start or soft pumpdown. The soft start process reduces turbulent flow during initial system evacuation, diminishing product contamination and damage. Often a bypass line is used to soft start a system, which utilizes system space and can clog, requiring frequent cleaning and maintenance. The Integrated LoPro (ILP) Two-Stage valve has been designed to replace the bypass line. The ILP accommodates the space constraints found on vacuum applications like loadlock and transfer chambers specifically in semiconductor or optical processing for which a cleaner environment is necessary. A heater jacket is available for processes with condensable materials.

Resources

Literature

- Integrated LoPro™ Two-Stage Valve (ILP) (2 MB, PDF)

Manuals

- Integrated LoPro™ Vacuum Valve (ILP) Manual (207.3 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity