DELTA™ II 2-zone Flow Ratio Controller

Overview

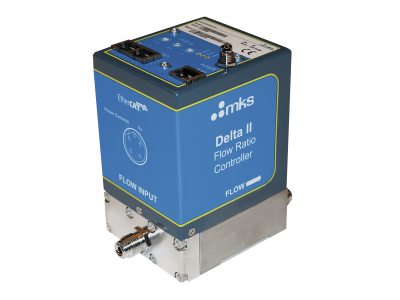

The DELTA™ series mass flow ratio controllers divide and control mixed process gas flows to either multiple chambers or zones within a process chamber at proportions specified by the user to optimize process uniformity and repeatability. DELTA™ series flow ratio controllers with their superior performance and compact design, are the latest offering from MKS, the industry leader in flow ratio control.

- Accurately and repeatably control flow ratio for better process optimization

- Digital control loop provides rapid response to channel set point independent of the gas mix

- Uses standard web browser with no special software required

Products

Configuration Options

The following options are available for DELTA II EtherCAT® Flow Ratio Controllers

Ordering Code Example: DLT2B052183R110

|

Configuration Option |

Option Code |

|---|---|

| DELTA II Flow Ratio Controller | DLT2B |

Reserved |

|

| Reserved | 0 |

Channel Flow Ranges (Flow 2/Flow 1) (XX*) |

|

| 500/500 | 52 |

| 1000/1000 | 13 |

| 2000/2000 | 23 |

| 3000/3000 | 33 |

| 5000/5000 | 53 |

| 10000/10000 | 14 |

Ratio (Flow 2:Flow 1) (Y) |

|

| 1:1 | 1 |

Connector (B) |

|

| EtherCAT | 8 |

Control I/O (C) |

|

| EtherCAT (units must select 3) | 3 |

Control Type (A) |

|

| Ratio: Q2/Q1 or Q1/Q2 | R |

Control Channel (Z) |

|

| Q1 Control: Q1/Q2 | 1 |

| Q2 Control: Q2/Q1 | 2 |

Firmware (QQ**) |

|

| Firmware Revision | 10 |

*For other ranges, consult factory.

**Unless otherwise specified, MKS will ship firmware revision current to date.

The following options are available for DELTA II Analog & DeviceNet Flow Ratio Controllers

Ordering Code Example: DLT2B052183R120

|

Configuration Option |

Option Code |

|---|---|

| DELTA II Flow Ratio Controller | DLT2B |

Reserved |

|

| Reserved | 0 |

Channel Flow Ranges (Flow 2/Flow 1)(XX*) |

|

| 500/500 | 52 |

| 1000/1000 | 13 |

| 2000/2000 | 23 |

| 3000/3000 | 33 |

| 5000/5000 | 53 |

| 10000/10000 | 14 |

Ratio (Flow 2:Flow1) (Y) |

|

| 1:01 | 1 |

Connector (B) |

|

| Analog - 9-pin Type D (MKS pinout) | A |

| DeviceNet - 5 pin microconnector | 6 |

Control I/O (C) |

|

| 0-5 VDC (analog devices) | 1 |

| 0-10 VDC (analog devices) | 2 |

| DeviceNet (DeviceNet units must select 3) | 3 |

Control Type (A) |

|

| Ratio: (DeviceNet units must select R) | R |

| Percentage: | P |

Control Channel (Z) |

|

| Q1 Control: Q1/Q2 or Q1/(Q1+Q2) | 1 |

| Q2 Control: Q2/Q1 or Q2/(Q1+Q2) | 2 |

Firmware (QQ**) |

|

| DeviceNet Firmware Revision | 20 |

| Analog Firmware Revision | 11 |

*For other ranges, Consult Factory

**Unless otherwise specified, MKS will ship firmware revision current to date.

***DeviceNet Units must select R

Specifications

-

TypeFlow Ratio Controller

-

Full Scale Flow Range500/500 sccm, 1000/1000 sccm, 2000/2000 sccm, or 10000/10000 sccm

(N2 equivalent) -

Ratio Accuracy±2% set point (for percent set points above 10%)

-

Channel Flow Control Range0, 5-100% Full Scale (EtherCAT)

-

Input Flow Range5-100% of each channel Full Scale rating (N2 equivalent)

-

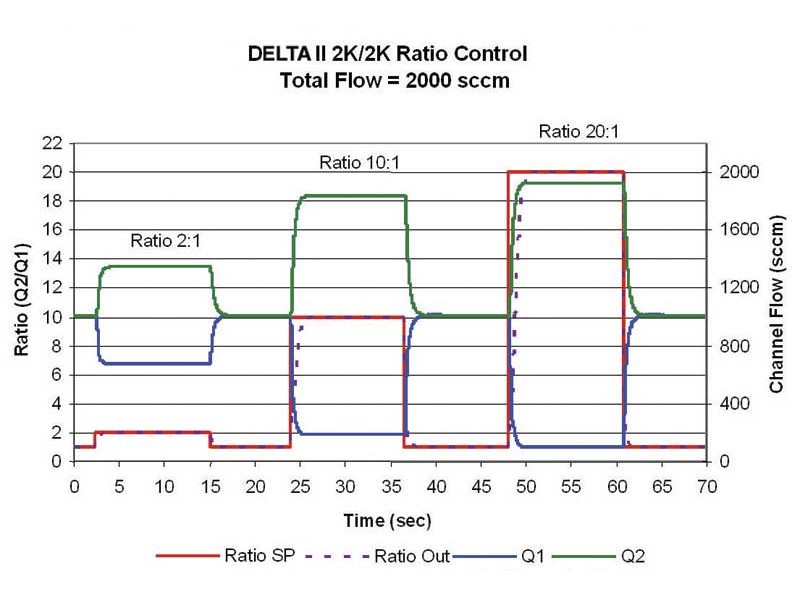

Ratio Control Range1:1 to 20:1 and 20:1 to 1:1

-

Ratio Repeatability & Reproducibility0.02% of channel Full Scale

-

Resolution0.02% of channel Full Scale

-

Maximum Operating Outlet PressureEtherCAT: 200 Torr at maximum flow rate through all channels

DeviceNet & Analog: 200 Torr -

Maximum Allowable Outlet Pressure DifferentialEtherCAT: 50 Torr with the same percentage flow through all channels (highest to lowest pressure channel)

DeviceNet & Analog: 50 torr (between Q1 and Q2) -

Normal Operating Pressure Differential<150 torr (<450 torr for 10000/10000) (N2)

-

Ratio Settling TimeEtherCAT: <3 seconds (typical dependent on downstream conductance matching)

DeviceNet: <3 seconds -

Input Ratio Range1:1 to 20:1 and 20:1 to 1:1 (EtherCAT)

-

Ratio Repeatability±0.3% of set point

-

Maximum Inlet Pressure150 psig (non-operational) (EtherCAT)

-

Zero Temperature CoefficientEtherCAT: <0.05% Full Scale/°C

DeviceNet & Analog: 0.05% Full Scale/°C -

Span Temperature CoefficientEtherCAT: <0.08% Reading/°C

DeviceNet & Analog: 0.08% Reading/°C -

Proof Pressure1000 psig (DeviceNet)

-

Burst Pressure1500 psig (DeviceNet)

-

Warm-up TimeEtherCAT: 60 Minutes

DeviceNet & Analog: 30 minutes -

Operating Temperature10-40°C

-

Storage Temperature-20-65°C

-

Storage Humidity0-95% relative humidity, non-condensing

-

Temperature Accuracy±2°C

-

Temperature Resolution0.1°C

-

Fitting Type4 VCR male (non-rotatable)

-

Display4 digits for value, 4 characters for unit

-

External Leak Integrity<1x10-10 (scc/sec He)

-

Leak Integrity Through Closed ValveEtherCAT: < 2% of Channel Full Scale at 400 Torr differential to < 1 Torr

DeviceNet & Analog: <2% of Channel FS at 400 torr differential -

Wetted Materials316 stainless steel VAR, 316 stainless steel, Inconel®, KM-45, PTFE

EtherCAT: Hastelloy® (sensor tube only) -

Surface Finish5 microinch average Ra

-

WeightLess than 5 lbs. (2.3 kg)

-

ConnectorAnalog: 9-pin Type "D" Male

DeviceNet: 5-pin DeviceNet microconnector

EtherCAT: 2 x RJ-45 (comm.) male, M8 male, 5 pin (power) -

Power RequirementsAnalog: +15-24 VDC ±5%

DeviceNet: 11-25 VDC

EtherCAT: 24 VDC ±10% (10 Watts) -

Power Consumption<9 Watts (DeviceNet)

-

CommunicationAnalog, DeviceNet, or EtherCAT

-

ComplianceCE (an overall metal braided, shielded able, properly grounded at both ends, is required during use).

Features

Wide Dynamic Ratio Control Range

The DELTA II has a wider dynamic ratio control range and is more adaptive to different tool and process conditions. MKS has developed a unique patent pending ratio control algorithm enabling ratio and flow response times of less than two (2) seconds. This control algorithm also enables a twenty to one ratio control range, more than double its industry leading predecessor.

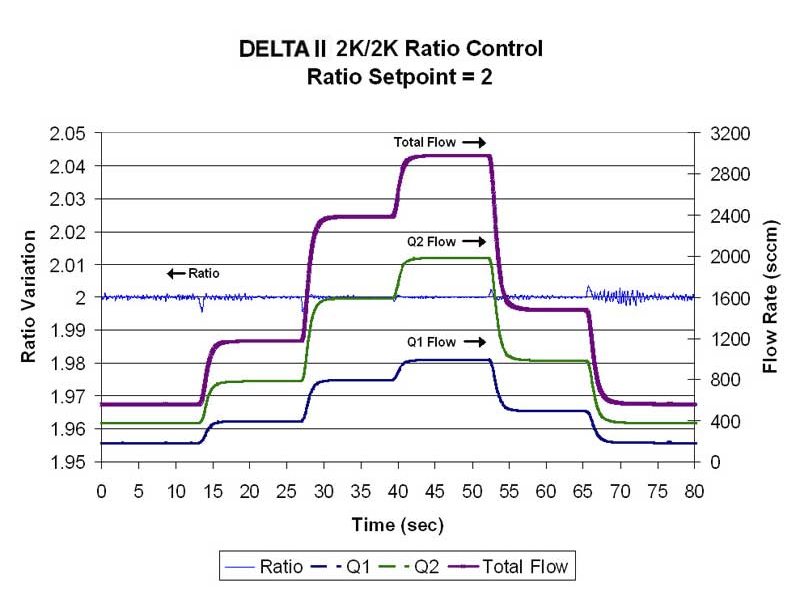

Tight Ratio Control While Changing Input Flow

The DELTA II maintains tight ratio control while the input flow is changed. Our unique patent pending ratio control algorithm enables ratio and flow response times of less than two seconds.

Embedded e-diagnostics

The DELTA II’s diagnostic feature allows the user to check the DELTA’s performance in-situ, lowering costs through reduced removal of “No Problem Found” devices. This feature is enabled through a web browser utility accessed through the device’s Ethernet port. This utility uses a standard web browser – no special software is required. For access, the IP address may be accessed through the devices bright LED display.

Flow Splitting Applications

Widely used in a variety of flow splitting applications such as etch, strip, and CVD, the DELTA II provides the user with the ability to distribute gas or gas mixtures to two different zones in a process chamber. Send the DELTA II a gas – or any mixture – and a ratio set point and the DELTA II will split the gas into two separate output channels automatically and precisely.

Throughput and process control have always been critical to the semiconductor device manufacturer. With the advent of 300 mm wafers and dual process chambers, new methods of control gas flow distribution have become increasingly needed. 300 mm wafer processing often requires tunable control of gas distribution across the wafer to provide better process uniformity. Dual process chambers require proper gas distribution for chamber matching from single source gas panels.

Controller 9-pin Connector Pin-outs

| Pin | Description |

|---|---|

| 1 | Valve Open/Close |

| 2 | Ration Signal Output |

| 3 | +15 VDC |

| 4 | Power Common |

| 5 | No Connection |

| 6 | Ratio Set Point |

| 7 | Signal Common |

| 8 | Signal Common |

| 9 | Remote Zero |

Resources

Literature

- DELTA™ II DeviceNet™ 2 Zone Flow Ratio Controller (2 MB, PDF)

- DELTA™ II EtherCAT® Flow Ratio Controller (259.8 kB, PDF)

- DELTA™ II Analog 2 Zone Flow Ratio Controller (2.9 MB, PDF)

Manuals

- DELTA™ II Flow Ratio Controller Pin-outs (39.7 kB, PDF)

- DELTA™ II 2-zone Flow Ratio Controller Manual (2.1 MB, PDF)

- DELTA II Communication Manual DeviceNet Supplement (475.2 kB, PDF)

- DELTA II Communication Manual EtherCAT Supplement (390.6 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity