Dynamic Frequency Tuning (DFT)

for RF Plasma Generators

- DFT produces significant performance gains in multi-frequency and pulsed RF power delivery systems

- Analytical approach guarantees optimal tuning solution

- DFT is >10 times faster than conventional tuning methods

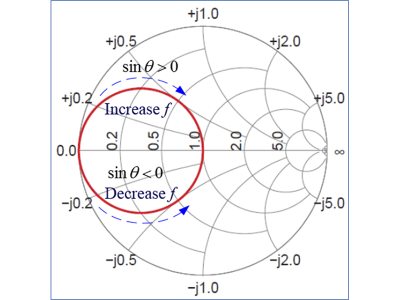

Dynamic Frequency Tuning (DFT) is a patented new software algorithm that is a significant advance over the guided-search auto frequency tuning (AFT) algorithms currently in use. DFT utilizes measured RF power distortion (sin?) to adjust the frequency of an RF power supply for optimal and instantaneous impedance tuning that minimizes reflected power and delivers precise set-point power to the plasma application. It is an optional feature for select RF generators at power levels ranging from 3KW to 13 KW and frequencies spanning 2MHz to 100MHz. DFT, with tune times of <50 µsec, provides substantially faster impedance tuning times than traditional guided search algorithms and other impedance tuning methods. The table below compares tuning methods of a standard variable vacuum capacitor matching network with ENI original Auto-Frequency tuning to the new patented Dynamic Frequency Tuning.

Comparison of Impedance Tuning Methods

| Tuning Method | Tune Time |

|---|---|

| Variable matching network | 2-3 sec |

| Variable matching network with pre-set positions | <1 sec |

| ENI Auto-frequency Tuning (AFT) | <500 µsec |

| ENI Dynamic-frequency Tuning (DFT) | <50 µsec |

| Published Competitive Frequency Tuning | <10,000 µsec |

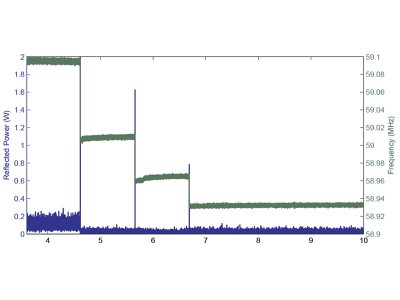

Power Variation

The instantaneous convergence of DFT is shown as the RF power was varied with uniform decreasing power steps from 150W to 75 W. The highest steady-state reflected power observed with DFT was <0.2 W. For the same power variations without DFT engaged, the steady-state reflected power reached approximately 47 W. This example shows the value of DFT for multi-step processes used in emerging etch and ALD processes.

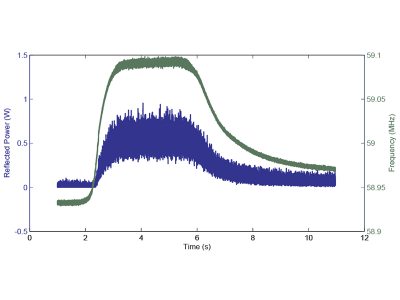

Power Variation

In a 150W CW RF plasma with DFT engaged, a pressure sequence from 100mT to 4mT and returning to 100mT was programmed. DFT maintained less than 1W reflected power during these transitions. Without DFT, similar pressure variations resulted in reflected power to 120W with eventual loss of plasma.

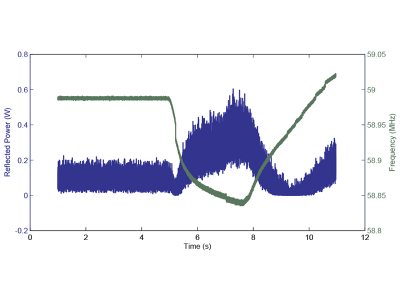

Flow Variation

For an O2 plasma source powered by 150W CW RF and the throttle valve control configured for fixed position, the mass flow controller was programmed to vary flow from 100 to 450 to 75 sccm. With DFT enabled, DFT controls the frequency of the power supply to retain reflected power less than 0.6W for the duration of the flow and pressure transitions. Without DFT engaged, the average reflected power was 21 W. Similar behavior was observed with Ar, He, and N2.

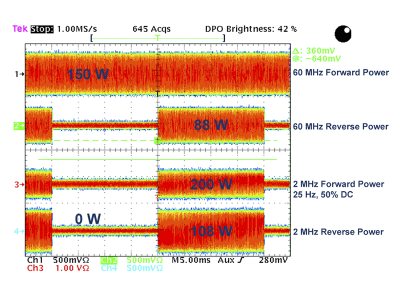

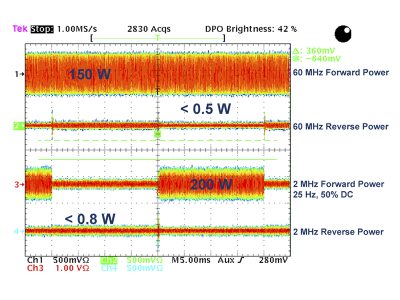

DFT Characteristics with Dual Frequency Pulsing Processes

- DFT maintained low (<1W) RF reflected power and impedance control effects within plasma transient time constants in a dual frequency, pulsed RF power delivery system. Without DFT reflected power in this system was >50% under similar conditions.

- The combination of RF pulsing technology and robust impedance tuning capabilities will assist in achieving next-generation nodes and improve process yield

Overall Summary

- DFT demonstrated instantaneous tuning and reflected power values of less than 1 W under conditions emulating process variations of power, pressure, and flow in a dual-frequency CW system and near instantaneous impedance tuning to achieve reflected power less than 1W within plasma transient time constants for pulsed systems. This capability is extended to solving the vexing challenge of source-only pulse on ICP reactors.

- DFT improves process capability for wide process window of operation.

- Enhance your RF power delivery to advance your process throughput, repeatability, and yield with this state-of-the-art impedance tuning system.

- MKS Advanced pulsing technology and newly patented impedance tuning methodology enables exceptional etch selectivity, profile control and thickness uniformity for manufacturing 3D NAND, FinFET, TSV and MEMs devices.

Ultra-High Velocity

Ultra-High Velocity