Vision 2000-B™ Vacuum Baseline Residual Gas Analyzers for Process Tools

Overview

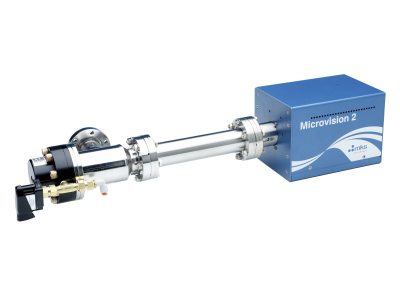

The Vision 2000-B™ is designed to track levels of potentially damaging residual gases that can negatively impact the quality of product – for example, aluminum deposition can be negatively impacted by the presence of O2 and H2 O, which can lead to poor bulk film characteristics and surface roughness. The Vision 2000-B features the “smart head” technology from the Microvision 2. The electronics unit mounts directly onto the analyzer head, and connects to the system PC via an ethernet interface.

- Monitor vacuum pumpdown, baseline, and leakback conditions

- 100 amu standard mass range with 200 amu or 300 amu options

- Process Eye™ Professional or optional TOOLweb® RGA software

- Simultaneous multiple-sensor operation capability

- Integration with tools for interdiction and alarms

- Alarm levels that dynamically change based on the slit valve positions

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

VISION-2000-B Vacuum Baseline Monitor, Process Tools, Vision 2000-B™ RGA |

|

Specifications

-

Mass Range1-100, 1-200, or 1-300 amu

-

Ion SourceOpen ion source

-

FilamentsReplaceable twin Tungsten or Thoria filaments

-

Mass FilterDouble filter (1 inch RF only pre-filter with 4 inch main filter)

-

DetectorDual (Faraday and secondary electron multiplier)

-

Maximum Analyzer Operating Pressure7.6e-5 Torr (1e-4 mbar)

-

Minimum Detectable ConcentrationFaraday: 2e-11 Torr (2.7e-11 mbar)

Secondary electron multiplier: 5e-14 Torr (6.7e-14 mbar) -

Mass StabilityBetter than ±0.1 amu over 8 hours

-

ResolutionBetter than 10% valley between peaks of equal height throughout the mass range

-

Mounting FlangeDN35CF (70mm/2.75inch OD) Conflat® flange

-

Vacuum HardwareAnalyzer housing plus pneumatic isolation valve. Optional independent total pressure gauge and/or valve and filament trip-box assemblies available for interlocked protection of the RGA.

-

Operating TemperatureElectronics: 10-40°C

-

WeightControl Module: 1.7 kg

-

Pneumatics60-80 psig CDA

-

Power Requirements24 VDC, 3.4A, external supply (included), 100-120V/200-240V, 2.1 Amp, 47-63 Hz

-

LED Status IndicationInterlock status, emission OK, SEM, power and communications

-

I/O Capability4 analog inputs (-11 to +11v, 22 bit)

2 analog outputs (0-10V, 12 bit)

16 digital TTL I/O

1 opto-isolated filament control input

1 dedicated gauge port -

Other FacilitiesLeak check headset socket, external filament trip and instrument reset

-

SoftwareProcess Eye® Professional fully network compatible control platform generating under Microsoft® Windows® 2000, xP* or Vista* (*recommended)

-

CommunicationEthernet CAT-5e

-

PC RequirementsIntel® Pentium IV® or AMD Athlon xP 1.2GHz, 1024 MB RAM, 120 GB disk free space drive. Multi-sensor installation may require higher specifications.

-

Simultaneous Multi-SensorMulti-Sensor Process Eye Professional client/server configuration offers flexible multi-sensor operation

-

Shipping Weight25 lbs (11.4 Kg)

-

ComplianceCE (control unit)

Features

Open Ion Source Analyzer

The open ion source analyzer incorporates twin filaments, where the second “back-up” filament enables continued operation in the event of a filament failure. The user serviceable analyzer design allows the ion source to be easily removed and dismantled for cleaning. The standard system includes a double-filter analyzer for increased sensitivity of higher mass species, contamination resistance and enhanced long term stability

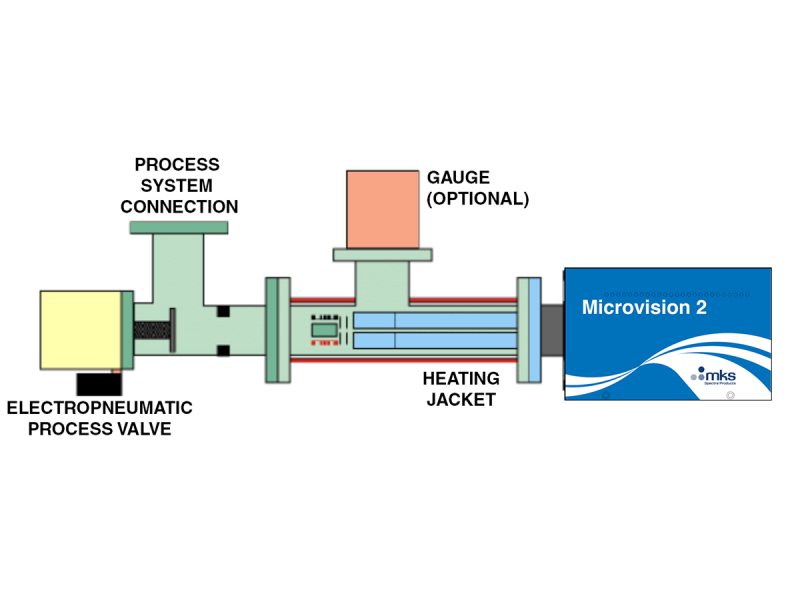

System Options

Systems can be equipped with a heater jacket and pneumatic isolation valve. A 3-way pneumatic valve for manual control of isolation inlet valve is standard and optional pressure switch assemblies can be chosen to detect within milliseconds when a valve has opened or closed on the tool. This provides Vision 2000-B systems with the flexibility to fully satisfy the application requirements of any vacuum baseline RGA process.

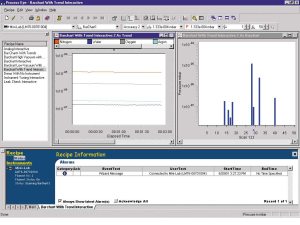

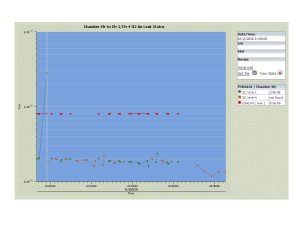

Process Eye™ Professional Control Platform

The Vision 2000-B analyzer uses Process Eye Professional, a highly flexible, modular application operating under 32bit or 64bit Windows XP, Vista, Server 2008 or Windows 7. Designed with a “client/server” structure, Process Eye Professional incorporates TCP/IP protocol for full network compatibility.

Process Eye Professional uses recipes to specify the way in which the instrument scans, displays data, and responds to the data acquired. Recipes are user configurable using the “Recipe Wizard” and are ideal for monitoring the various phases of repetitive recipes.

Recipes can be linked together to address different monitoring conditions or to facilitate automatic calibration (using pre-defined calibration recipes). The single button push (or external signal) initiation of a Process Eye Professional recipe eliminates the need for highly skilled, full time operators. The flexibility of Process Eye Professional allows recipes to be configured that will:

- Define data acquisition and data display parameters

- Display data in simultaneous “bar chart” and “data trend” formats, allowing the comprehensive and clear investigation of significant trend events

- Incorporate custom warnings and alarms, triggered or terminated when data highlights that process conditions have deviated from normal conditions or when specific events occur (e.g. valves opening/closing)

- Monitor and display other parameters as trends, in relevant units (temperature, gas flow rate, power, pressure, etc.) which are linked into the Vision 2000-B analyzer through its flexible analog and digital I/O

In addition, Process Eye Professional provides “live history” for quick on-line review of data trend events. Recently captured bar chart spectra are stored in a data buffer and can be reviewed by moving a cursor over the associated trend plot.

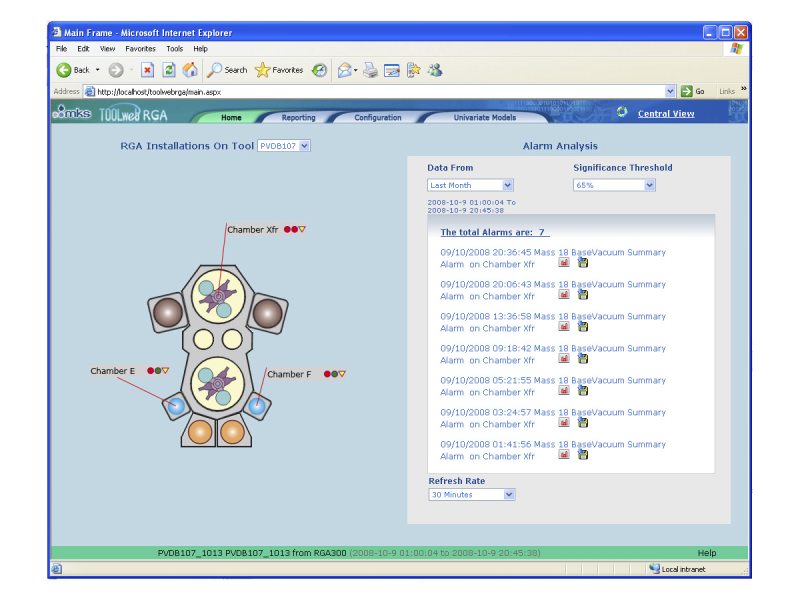

TOOLweb® RGA

Using TOOLweb RGA sensor integration option for process tools, the Vision 2000-B can be used as a transfer, buffer or loader chamber sensor in a completely automated process environment. TOOLweb RGA maintains a constant monitor of tool activities with all sensor data being framed by wafer logistics before alarm models are applied. Full alarm and data reporting to the FAB host and FDC are available so real time monitoring of chamber conditions and flagging of any process excursions from ideal conditions is possible.

Applications

The Vision 2000-B is an application specific instrument designed to monitor vacuum pumpdown, baseline, and leakback conditions on semiconductor and thin film process tools, and to alert of conditions that can negatively impact product yield. In addition, the Vision 2000-B provides the information required to optimize vacuum quality with:

- Residual gas monitoring, including air and water

- Contaminant monitoring, including Hydrocarbons

Resources

Drawings & CADs

- Vision 1000-B RGA Dimensional Drawing (82.9 kB, PDF)

Literature

- Vision 2000-B Vacuum Baseline Monitor RGA (297.1 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity