Microvision 2 Flexible, Integration-ready Residual Gas Analyzer

Overview

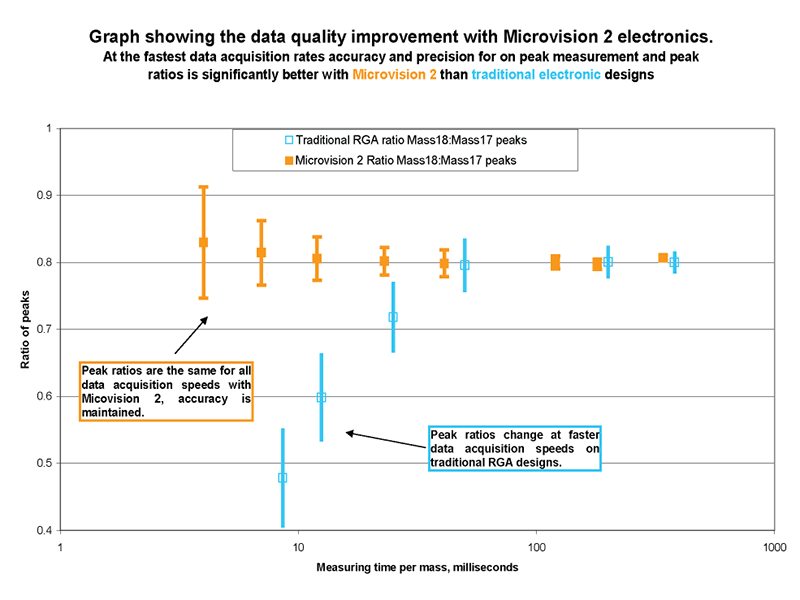

The Microvision 2 Residual Gas Analyzer is the latest innovation in RGA technology from MKS, designed to meet all of the traditional requirements for an RGA sensor but with data collection at speeds unachievable with previous generation technologies. In addition, the Microvision 2 is designed to collect data at millisecond speeds per data point even when measuring data over the full dynamic range of the RGA.

- Field proven quadrupole mass analyzer design

- Faster and more accurate responses in closed-loop control applications

- Acquire the highest quality of data at the fastest possible speeds

- Signals close to the noise floor can still be reliably measured

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

MICROVISION-2 Residual Gas Analyzer, Flexible and Integration-ready, Microvision 2 |

|

Specifications

-

Mass RangeDouble: 100, 200, 300 amu

5" Single: 100, 200 amu

Triple: 100, 200, 300 amu -

Faraday1.5 x 10-11 Torr

-

FilamentsTungsten or Thoria coated Iridium

-

Maximum Analyzer Operating Pressure7.6 x 10-5 Torr

-

Ion Source Sensitivity2.0 x 10-4 A/mbar

-

Minimum Detectable Concentration3 standard deviations of baseline noise at 300 ms integration

-

ResolutionBetter than 10% valley for peaks of equal height across mass range

-

Bake Out Temperature250°C (with extender or electronics removed)

-

Operating Temperature200°C Faraday only with electronics 10-40°C 150°C Multiplier with electronics 10-40°C and pressure <1e-8 mbar 90°C Multiplier with electronics 10-40°C and pressure <1e-5 mbar

-

UHV Out-gassing Rate< 1.0 x 10-9 mbar -l/s

-

Microchannel plate3.8 x 10-14 Torr

-

Single channel EM7.6 x 10-15 Torr (triple version)

-

Mounting FlangeDN 40 CF-F

Features

Microvision 2 Sensors

Microvision 2 has field proven quadrupole mass analyzer designs with pre-filters and optional post filters for:

- Greater resistance to the effects of contamination than a single filter

- Greater sensitivity at higher masses compared to single filters, critical to monitoring many molecules used in CVD processes

- Wide range of ion sources

- Twin independent filaments as standard to ensure minimum downtime during critical process monitoring

- Standard dual detector including a faraday detector and microchannel plate electron multiplier for detection to e-14 mbar partial pressures

Microvision 2 Electronics

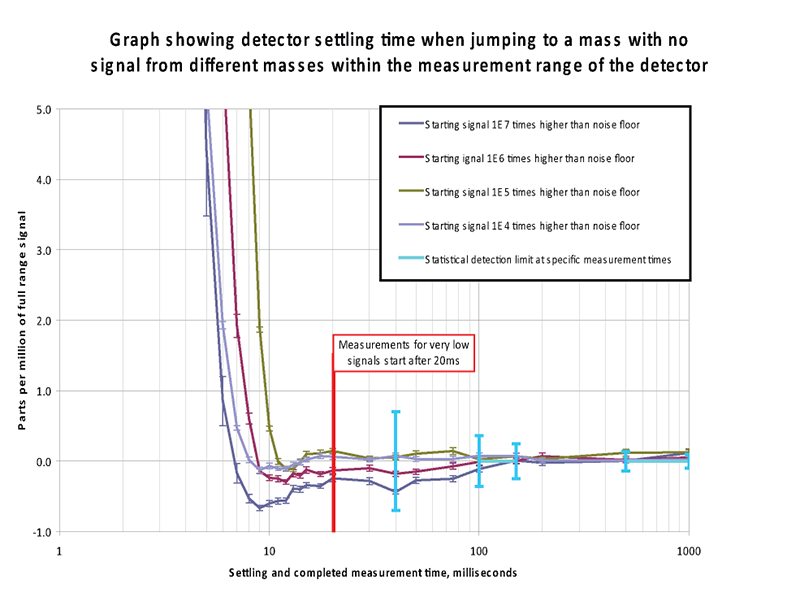

Data acquisition occurs through all solid state, wide dynamic range, fast settling detector electronics:

- Prevents large peaks from causing false positive measurements on small peaks

- Temperature stabilized critical components with improved signal stability and baseline drift allow the unit to be used without frequent recalibration if the vacuum chamber is stable but ambient air temperature fluctuates

- Variable sensor conditions to match the needs of each process

- Each optimization is separately stored in the RGA and automatically recalled or recalibrated by software recipes

- Flexible digital and analog I/O capability with a dedicated gauge port as standard

- Option to add extra levels of I/O and communications ports built into the RGA electronics

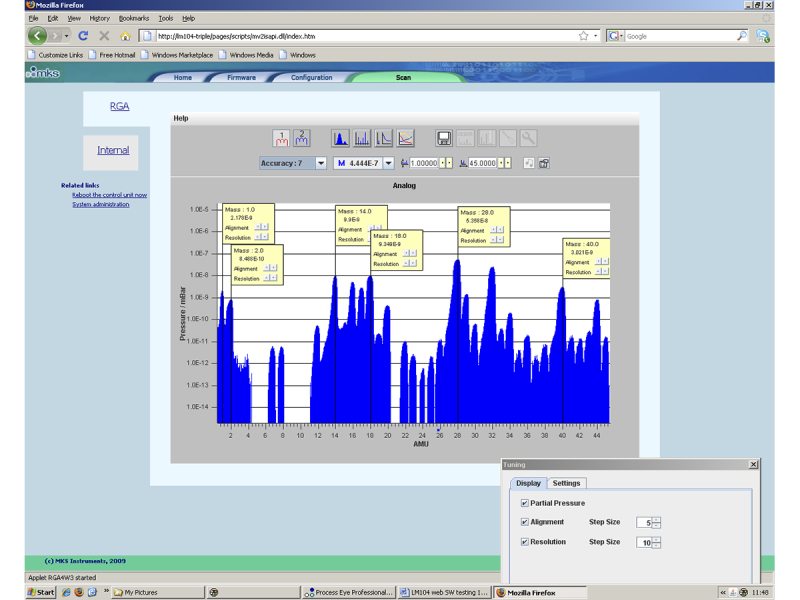

Built-in Web Interface

A web interface using industry standard technology allows control of the Microvision 2 as well as calibration, operation and data export through a non platform-specific web browser from anywhere on a network.

Using the documented ASCII protocol and TCP-IP communication, any third party software can send and receive commands and data from the Microvision 2.

Software Flexibility & Scalability without Compromise

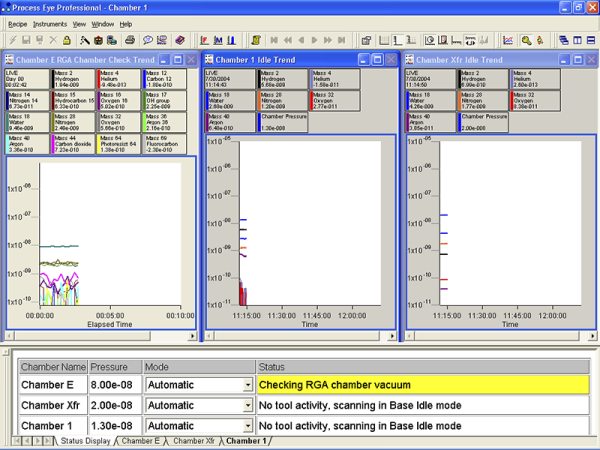

Process Eye Professional for flexible control through recipe-driven data collection

In addition to the standard, built-in web applications, software control is also available through three Windows applications, offering the best possible fit to any customer’s requirements.

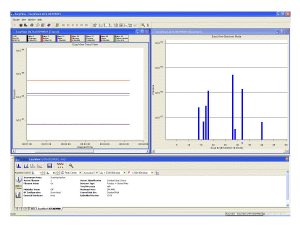

EasyView – provides basic RGA controls but with more functionality than the built-in web application:

- Store RGA data and review it later in the Recall viewer

- Annotate graphs with notes stored into the data files

- Run several RGAs from one software package

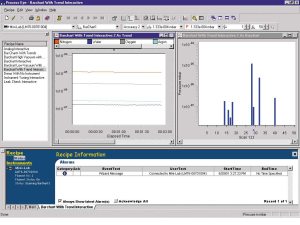

Process Eye Professional – offering complete control of all RGA parameters:

- Recipe driven control to allow the highest level of flexibility but with ease of use through the EasyView recipe and Recipe Wizard

- Ability to link to other systems through a variety of mechanisms such as Modbus, ASCII, SECS protocols, serial communications, TCP-IP, file exchange and many others

- Flexibility to run customized data collection, alarm condition checking and closed loop control operations

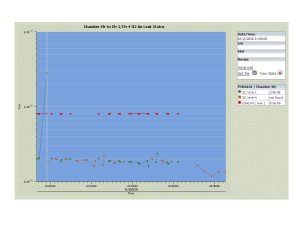

TOOL web RGA – specialized tool integration software providing optimized methods to get the most reliable information from RGAs on process tools:

- Complete integration of RGA data with tool operation and FDC systems

- Levels of interdiction from passive monitoring of the tool vacuum, to process critical go/stop control of individual process chambers

- Powerful web based reporting provides process engineers with highly valuable information to keep tools running at peak efficiency

Resources

Drawings & CADs

- Microvision 2 RGA Dimensional Drawing (281.2 kB, PDF)

Literature

- Microvision 2 Residual Gas Analyzer Datasheet (910.2 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity