PAC 100 Programmable Automation Controllers

Overview

- Fully programmable controller supports standard IEC 61131-3 environment

- Program template library supports common process applications, significantly reducing time to market

- ARM Cortex-M4, 100 MHz processor

- Function block library supports various MKS devices for 'plug & play' implementation

- Open standards support, interoperability with other devices & components

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

AS11870G-03 Programmable Automation Controller, PAC 100, Modbus TCP/IP Slave | $728 |

|

||||

|

AS11870G-05 Programmable Automation Controller, PAC 100, EtherCAT Slave | $801 |

|

Specifications

-

ProcessorARM Cortex-M4, 100 MHz

-

Operating SystemRTOS

-

Internal RAM256 MB

-

Expandable MemoryMicro SD, 1 or 2 GB

-

Dimensions35 x 125 x 92.3 mm (1.4 x 3.3 x 4.9 inches) (W x H x D)

-

Network InterfaceUSB OTG, 1 x RJ45 (Ethernet) 10/100Mbits/s

-

I/O InterfaceL-Bus

-

User InterfaceLEDs

-

Programming LanguagesLabVIEW, CWB, IEC61131-3 (with Ladder Logic, Structured Text, Function Block Diagrams, Instruction List, Sequential Function Charts, Software develop kit (SDK) option also available on MKS PACs to program in C/C++)

-

Code Space1 MB

-

Program Instances Per ResourceMultiprog ExPRESS: 11

Multiprog PRO: 1000 -

Project Tree Nodes8000

-

Program Instances per TaskMultiprog ExPRESS: 15

Multiprog PRO: 500

-

Included Libraries32

-

Local Variables Per POUMultiprog ExPRESS: 1500

Multiprog PRO: 15,000 -

Global Variables Per POUMultiprog ExPRESS: 5000

Multiprog PRO: 30,000 -

Tasks Per ResourceMultiprog ExPRESS: 5

Multiprog PRO: 16 -

Number of Supported I/Os Per Project128 Kbytes

-

Number of POU per ProjectMultiprog ExPRESS: 256

Multiprog PRO: 2000 -

I/O Groups200

-

Project Tree ConfigurationsMultiprog ExPRESS: 1/1

Multiprog PRO: 100/100 -

Power Supply24 VDC

-

Operating Temperature0 to 50°C

-

Storage Temperature-40 to 85°C

-

Humidity5-85% (non-condensing)

-

AltitudeUp to 2000 meters

Features

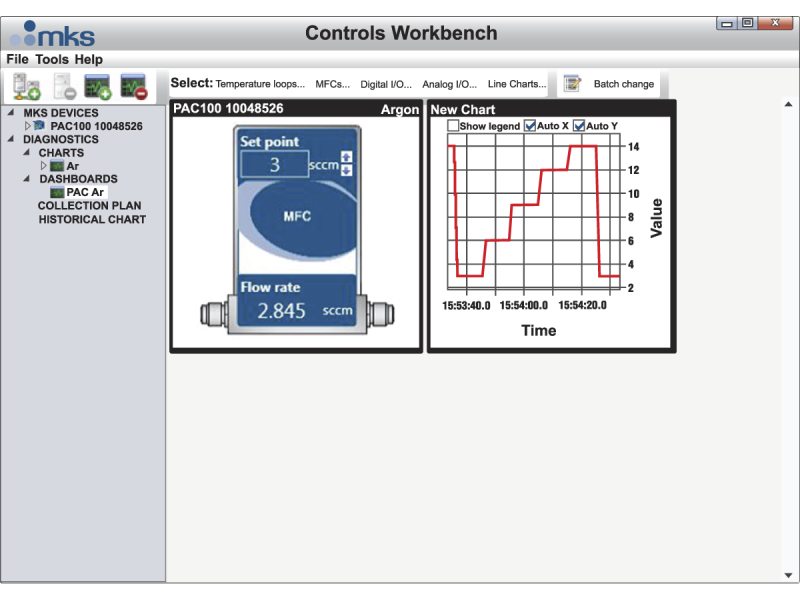

Controls Workbench Software

Controls Workbench software is an integrated, customizable software application that is included with the MKS Automation Platform. The CWB is a central, powerful interface that provides users a simple, complete solution for device configuration along with the ability to view, data log, chart and export process data, perform manual process control, process troubleshooting, and advanced tuning of the MKS controllers (PAC 1000, PAC 100, Communications Module, MultiTherm 2000 and MultiTherm 1000).

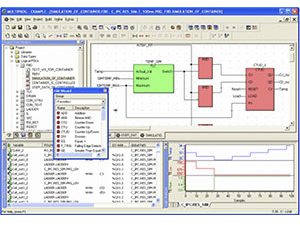

IEC61131-3 Programming Environment

The MKS Automation Platform supports a variety of programming environments, depending on user experience and requirements. The most common programming application for the MKS Automation Platform is the IEC61131-3 programming environment. The IEC61131-3 programming software allows users to create their programs and recipes in a global standard, IEC compliant programming environment. Recipes and projects can be created via a number of different or any combination of programming languages, creating an extremely flexible and capability programming environment. The programming interface supports developing a project using Ladder Logic, Structured Text, Function Block Diagrams, Instruction List, or Sequential Function Charts

Resources

Application Notes

- Seamless Integrated Automation Using the MKS Automation Platform (834.6 kB, PDF)

- Plug-and-Play Solution for Automation Control - Using the MKS Automation Platform with LabVIEW™ (494.8 kB, PDF)

- Real-Time Monitoring, Fault Detection and Reporting (1.4 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity