HPQ3 High Pressure 0.001 Torr Residual Gas Analyzer

Overview

Residual Gas Analysis (RGA) is a routine diagnostic tool for any vacuum engineer but the traditional upper working limit of 1e-4 mbar total pressure is restrictive for many process applications. The HPQ3 RGA allows operation up to 0.001 Torr without the need for differential pumping. The field proven technology of the HPQ analyser coupled with the latest innovative electronics platform derived from the Microvision 2 family give data quality not previously seen in this class of instrument. The resulting system is less complex, with reduced installation requirements, offering a higher level of reliability at a substantially lower cost.

- Upper working limit of 0.001 Torr total pressure

- Leak detection of vacuum lines, coolant lines, welds, and seals

- Chamber contaminant monitoring, including hydrocarbons

- Verify the quality of process gases

Products

Configuration Options

HPQ3 High Pressure Residual Gas Analyzer are available with the following options.

Ordering Code Example: 993-410-090

| Configuration Option | Option Code |

|---|---|

|

HPQ3 Residual Gas Analyzer |

993-410-09 |

Filament |

|

| Tungsten | 0 |

| Thoria coated iridium | 1 |

Specifications

-

Mass Range1-100 amu

-

FilamentsTwin Tungsten or Thoria Coated Iridium

-

DetectorFaraday

-

Maximum Analyzer Operating Pressure0.001 Torr (0.0013 mbar)

-

Minimum Detectable Partial Pressure8e-11 Torr (1e-10 mbar)

-

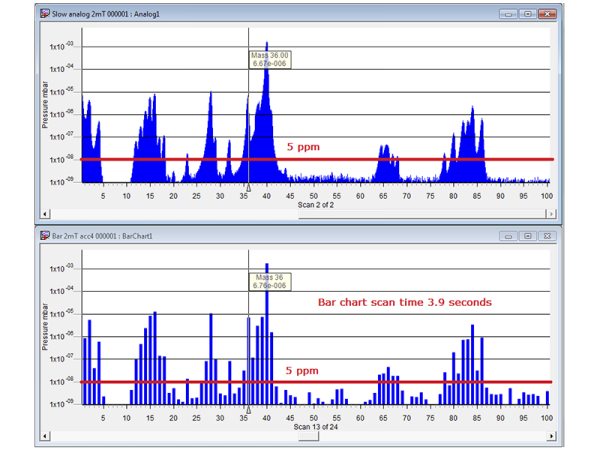

Minimum Detectable Concentration5ppm at 0.001 Torr (0.0013 mbar)

-

SoftwareBuilt-in web applications allowing RGA control and data acquisition using a platform independent web browser without the need for dedicated installed software Process Eye Professional and TOOLweb RGA Windows software packages for Windows xP, Vista or Win7 (32 and 64bit.)

-

Mass Stability±0.1 amu over 8 hours at stable ambient

-

ResolutionBetter than 10% valley for peaks of equal height across mass range

-

Mounting FlangeDN38CF (70mm/2.75inch OD) Conflat

-

Bake Out Temperature250°C with electronics removed

-

Operating TemperatureElectronics: 10-40°C

-

Power Requirements24V DC, 3A external universal voltage supply (included)

-

Maximum Operating Conditions80% RH (non condensing)

-

Data Acquisition MethodDedicated real time acquisition processor

-

Data Acquisition Speed< 3ms per point for analog or barchart scanning

-

Data Collection MethodsAnalog scanning, partial or full mass range 8, 16 or 32 points/amu Barchart scanning, partial or full mass range Peak-jump collection of any combination of peaks at up to 15 per acquisition set

-

Communication10/100 Base-T Ethernet, static or automatically assigned IP addresses

-

Settling Time< 20ms to 1 ppm of Maximum Signal

-

Control MethodCE operating system processor with web-server interface

-

Command StructureDocumented SDK and ASCII command protocols

-

Filament ProtectionDedicated x-Trip with optional pressure sensor for use with cryo-pump isolation valve.

-

ComplianceCE (control unit)

Features

RGA Technology Leadership

MKS was the first company to offer an RGA compatible with modern Ethernet based, web-enabled, wide area network installations. HPQ3 continues this development to a level that offers the highest flexibility and connectivity through the use of industry standard communication hardware and software. HPQ3 optimizes the roles required of a complex sensor by having two dedicated processors;

- An optimized, proprietary processor for data acquisition

- An industry standard CE operating system processor for external communications through field proven TCP-IP technology.

The advantages of this design approach are fast, accurate data from a robust RGA sensor using industry standard, flexible communication protocols. HPQ3 also provides a complete range of additional digital and analog connections for integrating into systems with flexible low cost solutions.

High Pressure Quadrupole Analyser

The new RF design in the HPQ3 covers the 1-100 amu mass range without compromising the quality of gas peak separation at very low mass or high mass. The field proven High Pressure Quadrupole analyser design in the HPQ3 retains the robust and inexpensive ion source design with dual filaments. This allows continuous uninterrupted operation without needing to regularly replace filaments before their normal expected lifetime. The HPQ3 can be used for processes where data is required up to a total pressure of 1.3 x 10-3 mbar.

Wide Dynamic Range Detector Electronics

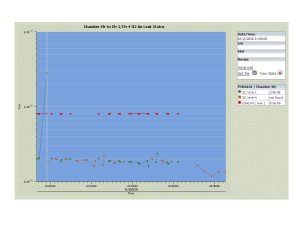

Wide dynamic range and high sensitivity allow parts per million level detection even at high pressures

The patented wide dynamic range detector electronics allow detection of single figure parts per million chamber leaks or contaminants, even when simultaneously measuring major gas peaks in the e-3 mbar range. This is possible in a single scan or peak jump data acquisition with less than 20 ms between the maximum and minimum signal levels and without the need for an expensive electron multiplier which needs frequent calibration and replacement.

- Prevents large peaks from causing false positive measurements on small peaks.

- Temperature stabilized critical components with improved signal stability and baseline drift allow the unit to be used without frequent recalibration if the vacuum chamber is stable but ambient air temperature fluctuates

- Variable sensor conditions to match the needs of each process under different pressure conditions

- Each optimized sensor configuration is separately stored in the RGA and automatically recalled or recalibrated by software recipes.

- Flexible digital and analog I/O capability with a dedicated gauge port as standard.

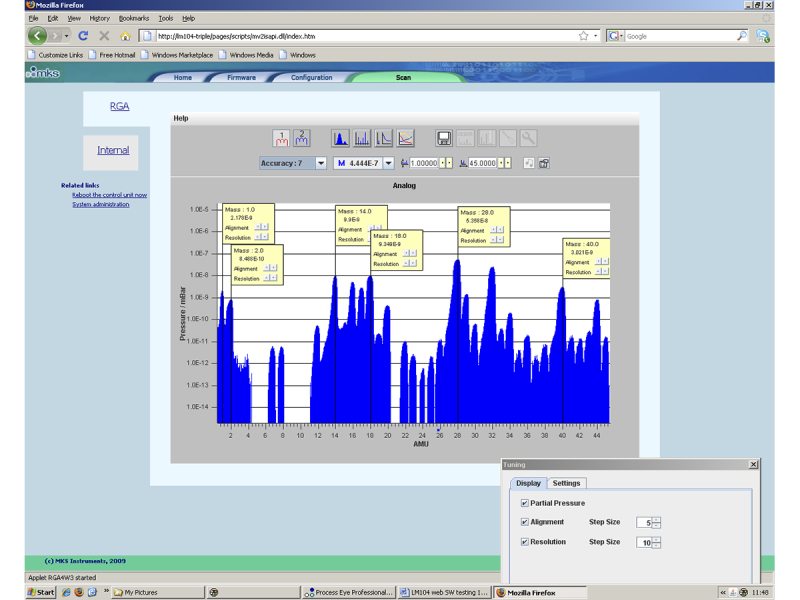

Built-in Web Server Application

A web interface using industry standard technology allows set-up and control of the HPQ3 from anywhere on a network. Using a non platform-specific web browser, calibration, operation and saving real time data to an export format is all possible. Using the documented Software Developer’s Kit, ASCII protocol and TCP-IP communication, any third party software can send and receive commands and data from the HPQ3 and HPQ3S.

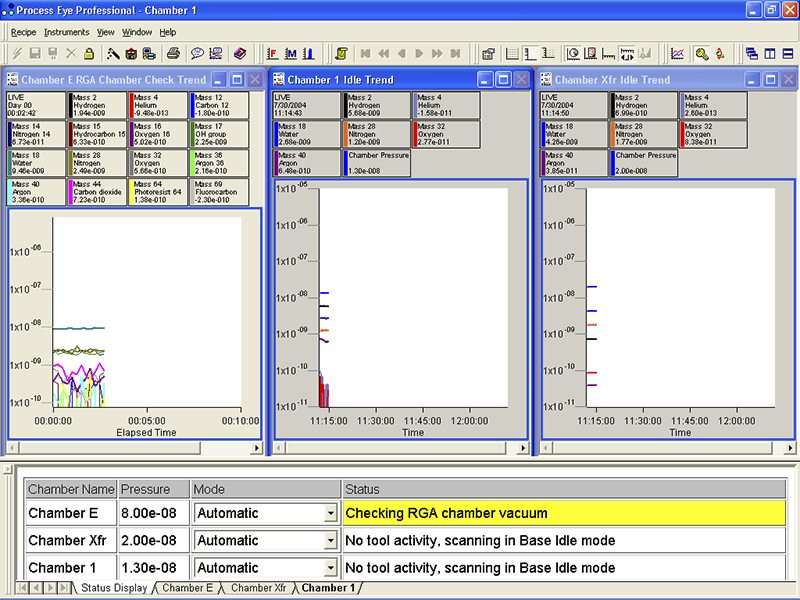

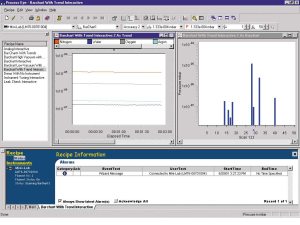

Process Eye Professional

A Windows-based comprehensive software platform offering complete control of all RGA parameters:

- Recipe driven control to allow the highest level of flexibility but with ease of use through the EasyView recipe and Recipe Wizard

- Ability to link to other systems through a variety of mechanisms such as Modbus, ASCII, SECS protocols, serial communications, TCP-IP, file exchange and many others

- Flexibility to run automatic and precisely-optimized data collection, alarm condition checking and closed loop control operation

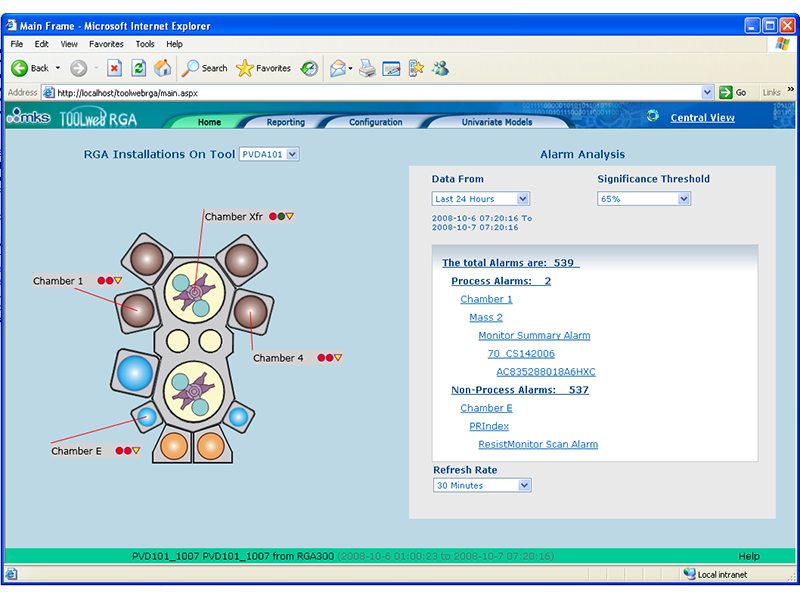

TOOLweb® RGA

A specialized, turn-key tool-integration software package (PC or server based) providing optimized methods to get the most reliable information from RGAs and other sensors on process tools:

- Complete integration of RGA data with tool operation and FDC systems

- Levels of interdiction from passive monitoring of the tool vacuum, to process critical go/stop control of individual process chambers

- Powerful web based reporting provides process engineers with highly valuable information to keep tools running at peak efficiency from anywhere on the network

Resources

Literature

- HPQ3/HPQ3S High Pressure Residual Gas Analyzer (RGA) (384.1 kB, PDF)

Drawings & CADs

- HPQ3/HPQ3S RGA Dimensional Drawing (127 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity