Chemical Downstream Plasma Source

Overview

The AX7610 is a microwave plasma source for remote plasma applications. With replaceable quartz or sapphire plasma tubes, the AX7610 downstream source offers configuration flexibility to meet the most demanding application process parameters. The quartz tube version is ideally suited for production of atomic oxygen, nitrogen or argon. The sapphire tube version is compatible with much more severe CF4 CHF3 and NF3 chemistries.

- Sapphire or quartz discharge tubes for Fluorine and non-fluorine chemistries

- Patented conductively-cooled design with high power and throughput

- Easy integration

- Wide application range

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

AX7610Q Chemical Plasma Source, 3 kW, Quartz |

|

|||||

|

AX7610S Chemical Plasma Source, 3 kW, Sapphire |

|

|||||

|

SA7610QTZ4 Plasma Source Tube Assembly, Quartz, AX7610 |

|

|||||

|

SA7610SAPP4 Plasma Source Tube Assembly, Sapphire, AX7610 |

|

Specifications

-

TypeAX7610 Downstream Plasma Source

-

Maximum Power3.0 kW

-

Electrical Requirements for UV Lamp24 VDC, 1.0 Amp

-

CoolingWater (3/8 in. Swagelok® fitting) 0.35 gpm, 30°C Max at 30psid minimum

-

Gas Line Connection1/4 or 3/8 inch VCR®

-

Output FlangeKF40, KF50 or custom

-

Process Gas SupplyQuartz Tube: O2, N2, H2O, Ar, non-fluorine based gases and perating pressure 1 to 8 Torr typical

Sapphire Tube: O2, N2, H2O, Ar, NF3, CF4, C2F6, and other Fluorine-based gases and operating pressure 2 to 8 Torr typical -

Dimensions15.3 in (388 mm) Long

-

Weight10 lb. (4.5 kg)

Features

Conductively Cooled Design

The patented conductively cooled design of the plasma tube supports high throughput and high power (up to 3kW) operation. The wide process window allows for AX7610 use in multiple applications, ranging from fast PR and polymer removal from 300mm wafers to fine-control low-k or atomic layer CVD processes.

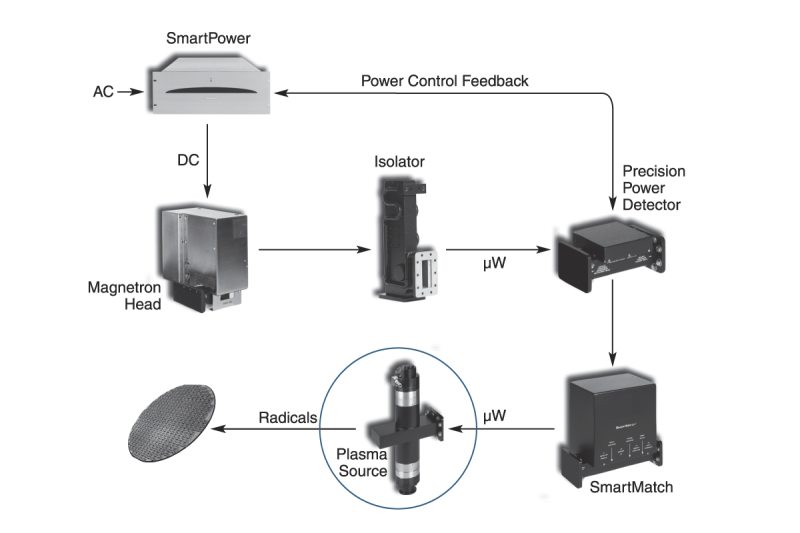

Microwave Plasma Systems

The AX7610 Source is designed to be used as a part of MKS microwave plasma system, including microwave power generator, waveguide components, and the advanced SmartMatch® intelligent matching unit.

The AX7610 can be offered in custom configurations, including different vacuum and waveguide interfaces, allowing for easy integration on customer chambers and application-specific performance optimization. MKS engineering and applications group will work with the customer to determine the optimum configuration.

Performance

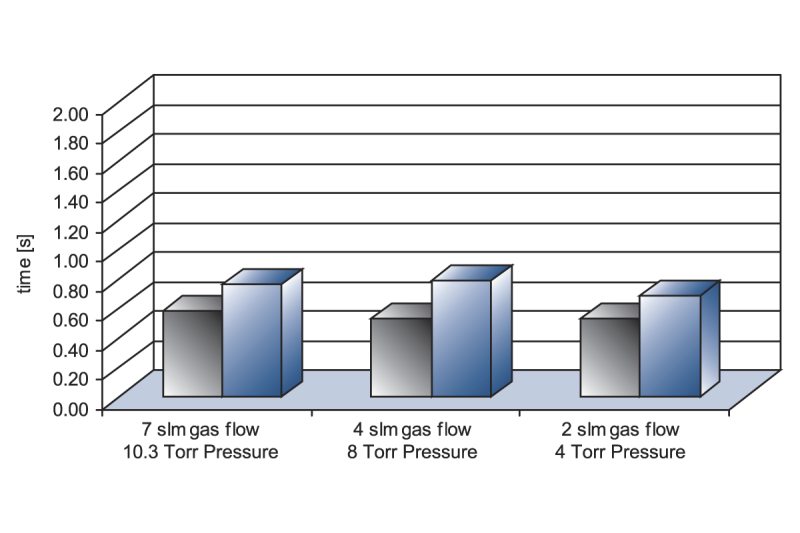

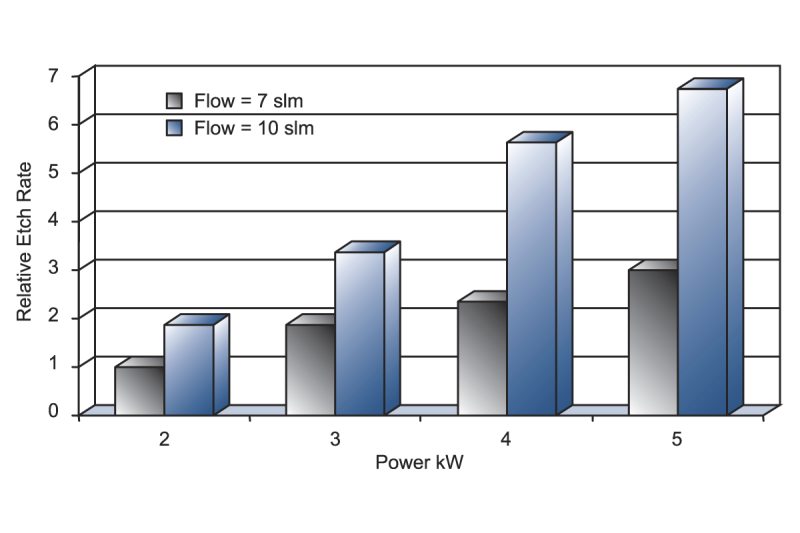

The AX7610 has a wide operating range in terms of both pressure and power, making it suitable for a wide variety of reactive gas applications including strip and passivation, chamber cleaning, and surface modification applications.

The AX7610 has been tested with a wide spectrum of process gases including O2, N2, H2, NH3, NF3, CF4, H2O, He, and Ar. The unit includes a plasma detection unit to interface with tool I/O and is fitted with a UV lamp for reliable plasma ignition. With an installed base of over 1000 units, MTBF exceeds 100,000 hours.

The AX7610 performance in customer-specific applications can be verified in the MKS state-of-the-art plasma lab.

Resources

Literature

- AX7610 Chemical Downstream Plasma Source (281 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity