Dissolved Ammonia Delivery System

Overview

The DI-Solver™ NH3 is a compact, stand-alone system designed to provide dissolved ammonia water for use in rinsing processes in the semiconductor industry. With Semiconductor 3D IC architectures using new materials like Cu-Co and Si-SiGe, the ability to wet clean with precise alkaline chemistries is growing in frequency and importance. The system is specifically designed to provide optimal cleaning capability at a given conductivity. The alkaline chemistry of dissolved ammonia provides ESD protection during rinsing, particle lift-off, and residual particle removal. It also prevents corrosion of metal interfaces, which is a common problem in semiconductor manufacturing. The system uses closed-loop control to keep conductivity and pressure stable under changing flow conditions. It also monitors and adjusts the NH4OH concentration to deliver the desired level of dissolved ammonia.

MKS' Di-Solver NH3 leverages the established and proven architecture of LIQUOZON® VariO3 Ozonated Water Delivery System, integrating high purity standard materials and safety features in a rugged system to meet the demands of advanced technology manufacturing.

- Best dynamic conductivity control and accuracy at point of use from proprietary control of gas

- Increases yields by inhibiting Electro Static Discharge

- Improves interconnect reliability and yield by preventing metal surface and post CMP clean corrosion

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

DI-NH3 Water Delivery System, Ammonia Water |

|

Specifications

-

Outlet PressureConfigurable 1.0-3.0 barg (3.7barg with outlet pump)

-

Plumbing MaterialsLiquid Wetted Surfaces: PFA, PTFE, quartz glass

Gas Wetted Surfaces: 316L stainless steel, PFA, PTFE -

CommunicationBinary in/out, RS232/RS485, analog 4-20 mA in/out, USB

-

DimensionsCoated steel, approximately 1810 mm high, 800 mm wide, 610 mm deep (71.2 x 31.5 x 24.1 in.)

Overall height: approx. 2000 mm (79 in.) -

Weight290-300 kg, depending on configuration

-

ComplianceCE, SEMI S2, SEMI F47, NRTL

Features

Benefits

Leading Technology

- Patented system to deliver dilute NH4OH based on ammonia gas ultra-pure water mixing

- Precise gas dosage through proprietary mass flow controller system

Process

- Precise conductivity control range of 5 to 121 μS/cm

- Up to 40 lpm flow

- Stable setpoint at varying flow rates

- Analog and digital communication with remote control

Reliability & Maintenance

- Repeatable unit to unit performance

- Field proven sub-components life

- Easy installation and operation

Performance & Operation

MKS’ DI-Solver NH3 leverages the established and proven architecture of LIQUOZON® Ozonated Water Delivery System, integrating high purity standard materials and safety features in a rugged system to meet the demands of advanced technology manufacturing.

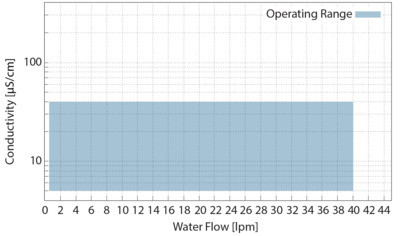

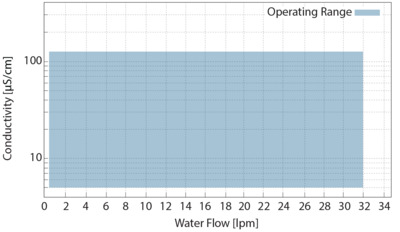

The below figures show the possible performance ranges of different configurations that provide a conductivity range of 5 to 40 μS/cm at 0.5 to 40 lpm (Figure 1), or 5-121 μS/cm at 0.5 to 32 lpm (Figure 2).

Specified achievable dissolved ozone concentration in UPW for a system pressure of 2.5 barg, a cooling water temperature and UPW temperature of 20°C.

Facility Requirements

N2: ≥ Grade 4 (purity ≥ 99.99%), dew point <-40°C

- Inlet Pressure: 4.5-7.6 barg (65-110 psig), at least higher 3 bar than system pressure

- Standard Flow Rate: ≤10 slm, according to SEMI E12 (0°C / 1.01325 bar)

Ammonia (NH3): ≥ Grade 4.5 (purity ≥ 99.995%)

- Inlet Pressure: 3.0-5.0 barg (44-73 psig)

- Standard Flow Rate: ≤ 2.0 slm, according to SEMI E12 (0°C / 1.01325 bar)

Ultra-Pure Water (UPW): <0.1 ppb metals, <10 particles/ml of 0.1µm size, free of organics

- UPW IN Pressure: 1.3-4 barg (14.5-73 psig), at least 1.3 bar higher than system pressure

- Temperature: 20-25°C (59-77°F), rated 20°C (68°F)

Clean Dry Air (CDA): Filtration, free of oils and particles

- Pressure: 6.0-8, 3 barg (87-120 psig)

- Flow Rate: ≤ 15 slm, typically 10.0 slm according to SEMI E12 (0°C / 1.01325 bar)

Exhaust:

- Cabinet Underpressure: >8mm (0.32 in.) water column

- Standard Flow Rate: >70m3/h, acc to SEMI S6 (21.1°C / 1.01325 bar)

Power: 200-208 V ±10%

Resources

Drawings & CADs

- DI-NH3 Dimensional Drawing (1 MB, PDF)

Ultra-High Velocity

Ultra-High Velocity