TOOLweb® RGA Process and Chamber Environment Software

Overview

- Detection of wafer borne contaminants

- Monitoring of process gas composition and purity

- Identification of chamber leaks

- Monitoring of chamber pump performance

- Highlighting of chamber issues to speed up PM recovery

- Chamber-to-chamber comparisons

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

TOOLWEB-RGA Chamber Monitor Software, Residual Gas Analyzer, TOOLweb® |

|

Features

Continuous Communication With the Tool

Through continuous communication with the tool, TOOLweb RGA is able to link process gas data with wafer logistics information and alarm or warn the tool in the event of a process excursion. Additionally, it can access other tool data (VIDs) using it for fault detection and sensor calibration, and incorporating it into TOOLweb RGA web-based reports. Wafer logistics information, tool VIDs, and the communication of “events” (e.g., wafer process start) are all required to drive the RGA state engine logic and ensure that there is correlation between sensor data and wafer specific information in the database. Additionally, TOOLweb RGA can send information in real-time to the tool, Fab host or an APC platform. Such information might include alarms, calculated indices, events, or sensor data.

Real-Time Applications

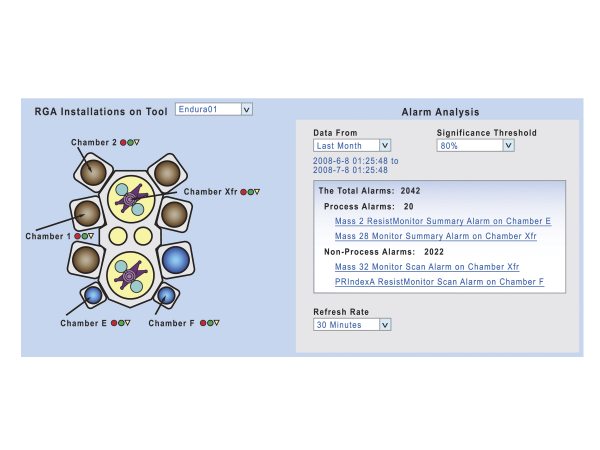

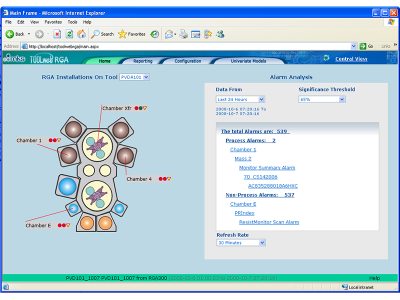

TOOLweb RGA dashboard showing tool sensor health status and real-time automated Pareto analysis of tool and process problems

The TOOLweb RGA real-time applications operate through the Process Eye Professional™ sensor control platform to ensure all installed sensors deliver stable, high quality data at all times. Included in the real-time applications is a fault detection and classification capability with multiple possible actions to be taken in the event of a process excursion.

A web-based application is provided to configure TOOLweb RGA and to make adjustments to alarm settings as well as the selection and configuration of tool VIDs for tracking. Real-time application features:

- Fully automated acquisition of RGA and independent sensor data throughout different tool chamber states (process, baseline, and pumpdown)

- Real-time displays of acquired data, alarm status, and sensor status

- Configurable for a range of different 200mm and 300mm process tools and offering a flexible approach to tool integration

- Performs self calibration at both process and base vacuum pressures

- Offers real-time fault detection with the ability to use statistical limits derived from univariate modeling

- Automatic selection of alarms on the basis of wafer type (lot) and process recipe

- E-mail notification of alarms and warnings to defined recipient groups

- Alarm conditions can be sent to the tool controller and may be used to stop the tool or hold a contaminated wafer while others complete processing

Web-Based Applications

The tool dashboard provides an instant view of the status of the tool, the health of each sensor, and the latest alert status for the chambers. It also provides an automated Pareto analysis of the warnings and alarms from the sensors being monitored on the tool. Instead of running a report for each chamber or process, a web page link makes it possible for engineers to see at a glance any recurring problems and to drill down further into the data. From the tool dashboard it is possible to link to all of the TOOLweb RGA web pages.

The web-applications included with the TOOLweb RGA product suite offer data reporting and database search capabilities and are accessible from any location on a network (or over the internet) using a web browser with no requirement for software installation or downloading. Web-applications typically run on the same control PC as the real-time applications, however, the database and data files may be located on a separate server on the same network.

Data Summary Reports

- Available for different tools and chambers over defined periods of time with specific reports for process, base line and pumpdown conditions.

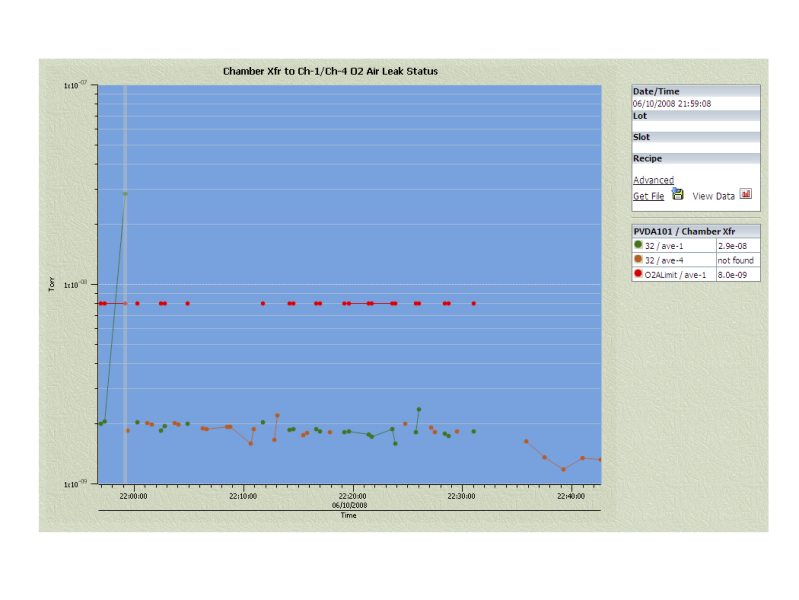

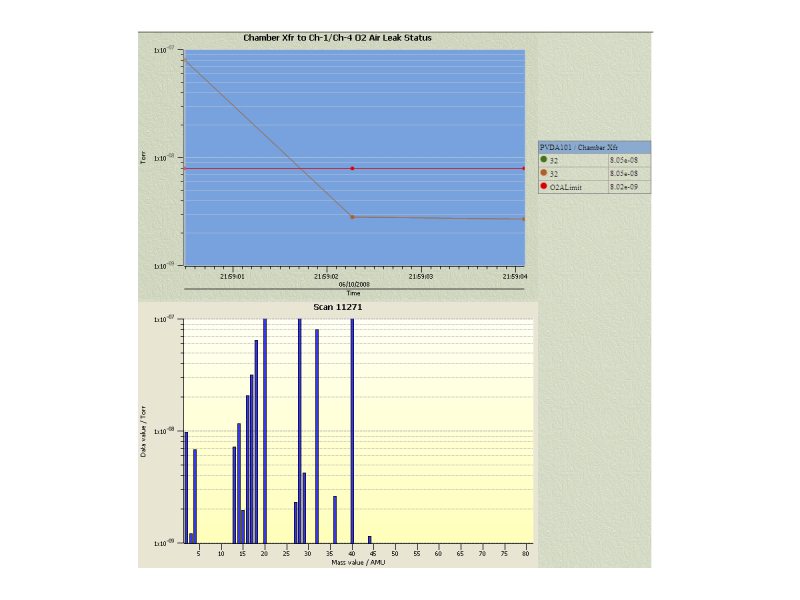

- Click on outlier wafers within a report to identify numeric data values, Lot ID, wafer ID, and process recipe. Drill down to see “raw” bar chart and trend data collected during wafer processing

- Reports can be filtered to show only a subset of wafers that were processed by specified process recipe(s), be longing to certain lots etc.

Favorite Reports

- Similar to standard data summary reports but with predefined tool, chamber, and time period. Allows chamberto-chamber comparisons to be made within the same report and includes wafer identification and drill-down to view “raw” data.

Wafer Search

- Operator can search for a specific wafer or lot; and drill down to view “raw” RGA, sensor, and VID data.

Summary Alarm Search

- Automatically lists alarm and warning events occurring on a particular tool and chamber over a specific period of time and provides a summary of the root cause. Includes drill down capability to view “raw” RGA and VID data

Complex FDC Modeling

- By using data captured during the normal processing of wafers, TOOLweb RGA builds statistical models using both “raw” and “summary” RGA, sensor, and VID data

- These models can either be created by the internal tools of TOOLweb RGA or the data can be exported in realtime to an external MKS or 3rd party data processing package for fault determination.

- The returned real-time result of the FDC analysis can be automatically re-imported into TOOLweb RGA for alarm actions and for use in standard reporting methods.

Resources

Application Notes

- TOOLweb® RGA Connectivity and Scalability (411.4 kB, PDF)

- Increased Electron Multiplier Lifetimes Through Intelligent Data Acquisition (224.9 kB, PDF)

Literature

- TOOLweb® RGA Automated Process and Chamber Environment Monitor (275.7 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity