Vision 2000-P™ Residual Gas Analyzers for Select Pressure & PVD Processes

Overview

The Vision 2000-P™ represents a different concept in process monitoring, requiring minimum operator interaction or RGA knowledge. The Vision 2000-P incorporates the “smart head” RGA technology of the Microvision 2 with a closed ion source and close-coupled inlet. This state-of-the-art RGA technology is integrated with Process Eye™ Professional Control Platform, a recipe based, user-configurable software program. The advanced technology available in the Vision 2000-P provides users with simple, effective, process monitoring operation.

- ppb level detection of contaminant gases during PVD processes

- Track process gas mixture composition when two gases are utilized

- Vacuum troubleshooting for fast PM recovery

- Can be integrated with a wide variety of PVD tools

- Remote Vacuum Controller (RVC) for fail-safe PC-based operation and control

- Available with Process Eye Professional software

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

VISION-2000-P Process Monitor, Select Pressure & PVD Applications, Vision 2000-P™ |

|

Specifications

-

Mass Range1-100, 1-200, or 1-300 amu

-

Ion SourceHigh conductance closed ion source

-

FilamentsReplaceable twin Tungsten or Thoria filaments

-

Mass FilterDouble filter (1 inch "RF only" pre-filter with 4 inch main filter)

-

DetectorDual (Faraday and secondary electron multiplier)

-

Maximum Analyzer Operating Pressure7.6e-3 Torr (1e-2 mbar) at the ion source inlet (standard), higher pressure optional

-

Minimum Detectable Partial Pressure<2e-11 Torr (for total pressures <1 x e-4 Torr on inlet)

-

Minimum Detectable Concentration<100ppb for all common gases except <10ppm for H2 (trace gas detection limit)

-

Mass StabilityBetter than ±0.1 amu over 8 hours

-

ResolutionBetter than 10% valley between peaks of equal height throughout the mass range

-

Mounting FlangeDN35CF (70mm/2.75 inch OD) Conflat® flange

-

Vacuum Hardware60 l/s Turbomolecular pump with high conductance analyzer housing, inlet system, right angle valve, automated vacuum controller (RVC) completely inter locked and integrated.

-

Analyzer Housing Base PressureBetter than 5e-9 Torr after bakeout

-

Bakeout Temperature and Bakeout JacketIncluded for 180°C bakeout

-

Operating TemperatureElectronics: 10-40°C

-

Mechanical SupportOptional stands and brackets are available

-

Mobile RGA PlatformOptional RGA trolley to improve versatility (footprint 18x24 inches, 455x604 mm)

-

Pneumatics60-80 psig CDA

-

Power Requirements88-264 VAC, 47/63 Hz, 600 Watts

-

Maximum Operating Conditions80% RH (non condensing)

-

LED Status IndicationInterlock status, filament emission, SEM, power and communications

-

I/O Capability4 analog inputs and 2 outputs (plus 1 dedicated gauge input). Optional support for a large number of both analog and digital inputs and outputs, including relay control

-

Other FacilitiesLeak check headset socket, external filament trip socket, instrument reset

-

SoftwareProcess Eye Professional fully network compatible control platform generating under Microsoft® Windows® 2000, xP* or Vista* (*recommended)

-

CommunicationEthernet CAT-5e

-

PC RequirementsIntel® Pentium IV® or AMD Athlon xP 1.2GHz, 1GB RAM, 120 GB hard drive, dependent upon total number of sensors on the computer and the operating system in use. Multi-sensor installation may require higher specifications.

-

Simultaneous Multi-SensorProcess Eye Professional client/server configuration offers flexible multi-sensor operation

-

Shipping Weight44 lbs (20 Kg)

-

Foreline PumpDry diaphragm standard; Other options available

-

ComplianceCE (control unit)

Features

Closed Ion Source

Each Vision 2000-P incorporates a closed ion source and a custom inlet valve with an optimized high conductance, low surface area path to the PVD process chamber. With this source, the system is able to monitor the complete PVD process cycle, from base vacuum to process pressures of up to 0.01 mbar, without the need for a pressure reduction inlet.

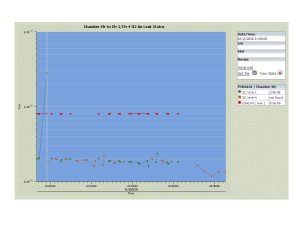

By maximizing the ratio between process gas signals and the gas background in the differentially pumped Vision 2000-P analyzer housing, the closed ion source enables ppb levels of detection for trace contaminants in the process gas. Exceptionally good residual hydrogen detection can be achieved with the high performance electronics.

Remote Vacuum Controller

Each Vision 2000-P system incorporates a Remote Vacuum Controller (RVC) module that provides fail-safe protection for both the process tool and the RGA.

Furthermore, it allows full operation and control of RGA system components (filaments, pumps, inlet valves, etc.) from the system PC. The compact, remotely mounted rack module includes the RVC and power supplies. The unit is easily mounted onto any standard 19 inch tool rack for mounting on a process chamber or other compatible location. 33 ft. (10 m) cables for ease of remotely locating the probe assembly are included as standard.

Mobile RGA Platform

Any Vision 2000-P can be mounted on a mobile RGA platform with the convenience of being able to move the RGA easily between chambers as the need arises. The mobile platform has an integrated laptop table and mounts the electronics on the trolley. Using a standard 10 foot (3m) cable loom the platform can be conveniently located away from the RGA mounting point on the tool chamber.

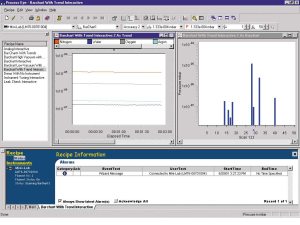

Process Eye™ Professional Control Platform

The Vision 2000-P analyzer uses Process Eye Professional, a highly flexible, modular application operating under 32bit or 64bit Windows XP, Vista, Server 2008 or Windows 7. Designed with a “client/server” structure, Process Eye Professional incorporates TCP/ IP protocol for full network compatibility. Process Eye Professional uses recipes to specify the way in which the instrument scans, displays data, and responds to the data acquired. Recipes are user configurable using the “Recipe Wizard” and are ideal for monitoring repetitive processes and analyses.

Associated bar chart spectra and recently captured spectra are stored in a data buffer for easy review. Recipes can be linked together for the optimum monitoring of various phases of a particular process, or to facilitate automatic calibration using pre-defined calibration recipes. The single button push (or external signal) initiation of a Process Eye Professional recipe eliminates the need for highly skilled, full time operators.

The flexibility of Process Eye Professional allows recipes to be configured that will:

- Define data acquisition and data display parameters, along with any on-line data processing required to convert data into relevant units and information

- Display data in simultaneous “bar chart” and “data trend” formats, allowing the comprehensive and clear investigation of significant trend events

- Incorporate custom warnings and alarms, triggered or terminated when data highlights that process conditions have deviated from normal conditions

- Monitor and display other parameters as trends, in relevant units (temperature, gas flow rate, power, pressure, etc.) which are linked into the Vision 2000-P analyzer through its flexible analog and digital I/O

In addition, Process Eye Professional provides “live history” for quick on-line review of data trend events. Recently captured bar chart spectra are stored in a data buffer and can be reviewed by moving a cursor over the associated trend plot.

Applications

The Vision 2000-P is an application-specific process monitoring system designed to monitor contamination levels within semiconductor and thin film PVD process tools and to alert of conditions that can negatively impact product yield. In addition, the Vision 2000-P optimizes vacuum quality with:

- Contamination monitoring, including hydrocarbons, to sub-ppm levels during PVD process

- Residual gas monitoring, including air and water

Resources

Application Notes

- Silicone Oil Leakage Detection in Freeze Dryer Systems (405.6 kB, PDF)

Drawings & CADs

- Vision 2000-P™ XD Dimensional Drawing (310.9 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity