Vision 2000-C™ & Vision 2000-E™ Residual Gas Analyzers for Multi-pressure & CVD/ALD Processes

Overview

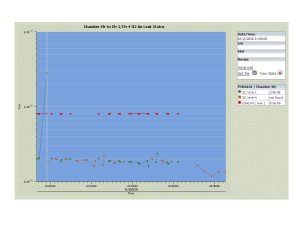

- Continuous in situ monitoring of CVD and etching processes

- Baseline monitoring for air leaks and background contamination

- Includes Process Eye™ Professional RGA software

- Can be integrated with a wide variety of CVD and Etch tools

- Remote Vacuum Controller (RVC) for failsafe vacuum operation

- Vacuum troubleshooting for fast PM recovery

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

VISION-2000-C CVD or Etch Process Monitor, 1-300 amu, Multi-pressure & CVD/ALD |

|

|||||

|

VISION-2000-E CVD or Etch Process Monitor, 1-200 amu, Multi-pressure & CVD/ALD |

|

Specifications

-

Mass RangeVision 2000-C: 1-300 amu

Vision 2000-E: 1-200 amu -

Ion SourceHigh conductance closed ion source

-

FilamentsIndependently replaceable twin Tungsten filaments

-

Mass FilterDouble filter (1-inch "RF only" pre-filter with 4-inch main filter)

-

DetectorDual (Faraday and secondary electron multiplier)

-

Maximum Analyzer Operating Pressure1e-3 Torr at the ion source inlet (standard), higher pressure optional

-

Minimum Detectable Partial Pressure<2e-11 Torr (for total pressures <1e-4 Torr on baseline inlet)

-

Minimum Detectable Concentration<200 ppb of highest pressure gas for non-interfering species

-

Mass StabilityBetter than ±0.1 amu over 8 hours

-

ResolutionBetter than 10% valley between peaks of equal height throughout the mass range

-

Base Pressure RangeIon source at maximum pressure at 1 mTorr, 10 mTorr or 100 mTorr

-

Process Pressure RangeIon source at maximum pressure at 10 mTorr, 100 mTorr, 500 mTorr, 1.5 Torr, 5 Torr, 10 Torr, 40 Torr, 100 Torr or 700 Torr

-

Mounting FlangeDN35CF (70mm/2.75 inches OD) Conflat® flange. Custom adapters can be provided.

-

Vacuum Hardware60 l/s turbomolecular pump with high conductance analyzer housing, inlet system, UniBloc™ inlet, automated vacuum control (RVC) completely interlocked and integrated

-

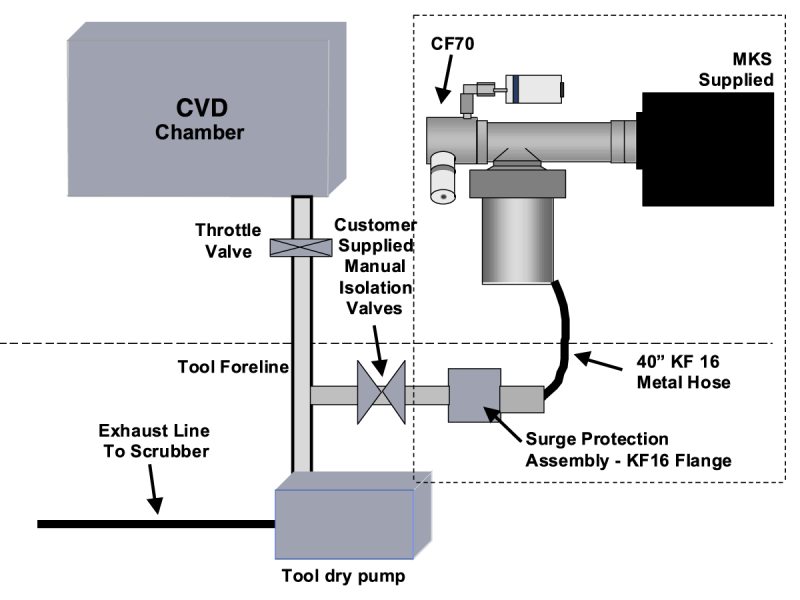

Backing Vacuum SystemStandard: Connected to the tool foreline pump via Surge Protect assembly with a KF16 fitting

Optional: Independent chemically resistant, dry diaphragm pump with KF16 fitting for connecting the exhaust to a suitable scrubber system -

Operating TemperatureElectronics: 10-40°C

-

WeightControl Module: 1.7 kg

-

Mechanical SupportOptional stands and brackets are available

-

Mobile RGA PlatformOptional RGA trolley to improve versatility (footprint 18x24 inches, 455x604mm)

-

Pneumatics60-80 psig CDA

-

Power Requirements88-264 VAC, 47/63 Hz, 600 Watts

-

Maximum Operating Conditions80% RH (non condensing)

-

LED Status IndicationInterlock status, filament emission, SEM, power and communications

-

I/O Capability4 analog inputs and 2 outputs (plus 1 dedicated gauge input). Optional support for a large number of both analog and digital inputs and outputs, including relay control

-

Other FacilitiesLeak check headset socket, external filament trip socket, instrument reset

-

SoftwareProcess Eye® Professional fully network compatible control platform generating under 32bit or 64bit Microsoft® Windows® xP, Vista, Server 2008 or Windows 7* (*recommended)

-

CommunicationEthernet CAT-5e

-

PC RequirementsIntel® Pentium IV® or AMD Athlon xP 1.2GHz, 1GB RAM, 120 GB hard drive, dependent upon total number of sensors on the computer and the operating system in use. Multi-sensor installation may require higher specifications.

-

Simultaneous Multi-SensorProcess Eye Professional client/server configuration offers flexible multi-sensor operation.

-

Shipping Weight44 lbs (20 Kg)

-

ComplianceCE (control unit)

Features

ppm Level Detection for Trace Contaminants

By maximizing the ratio between CVD or Etch chamber gas signals and the gas background in the differentially pumped Vision 2000-C and Vision 2000-E analyzer housing, the closed ion source enables ppm-level detection for trace contaminants in the process gas. The closed ion source analyzer is manufactured from vacuum prepared stainless steel and high density alumina ceramics, and features independently replaceable twin filaments to provide built-in backup in the event of a filament failure. The standard system includes a double filter analyzer for increased sensitivity of higher mass species, contamination resistance and enhanced long-term stability.

Remote Vacuum Controller

Each Vision 2000-C and Vision 2000-E system incorporates a Remote Vacuum Controller (RVC) module that provides fail-safe protection for both the process tool and the RGA. It allows full operation and control of RGA system components (filaments, pumps, inlet valves, bakeout, etc.) from the system PC. The compact, remotelymounted rack module includes the RVC and power supplies. The unit is easily mounted onto any standard 19” tool rack for mounting on a process chamber or other compatible location. Thirty three foot (10 m) cables are included as standard so that the probe assembly can be located in a remote position.

Mobile RGA Platform

Any Vision 2000-C or Vision 2000-E can be mounted on a mobile RGA platform with the convenience of being able to move the RGA easily between chambers as the need arises. The mobile platform has an integrated laptop table and mounts the electronics on the trolley. Using a standard ten foot (3m) cable loom the platform can be conveniently located away from the RGA mounting point on the tool chamber.

UniBloc™ Inlet Valve

The exclusive fast response UniBloc™ inlet valve allows sampling at both background and process pressure through orifices selected for the pressures to be encountered. When not sampling, both the valve and analyzer are automatically isolated from the process chamber and purged with inert gas. Purging is done through the mass spectrometer pumping systems, not through the process chamber. Purging is also used during bake-out, reducing initial startup time and residual background recovery time. The inlet valve is operated by integrated electronics and controlled via recipes from Process Eye Professional. The required valve selection is made automatically by a gas independent pressure sensor in the UniBloc inlet which also provides a readout of the process chamber total pressure in the Process Eye Professional software.

Computer-aided design was utilized to engineer the Unibloc to have minimal internal volumes and surface areas. The internal seals are Kel-F® for compatibility with CVD and Etch process gases. The external seals are all metal. A conformal heating jacket provides temperature control to minimize deposition within the valve and to maintain mobility of sticky/polar gases through the inlet.

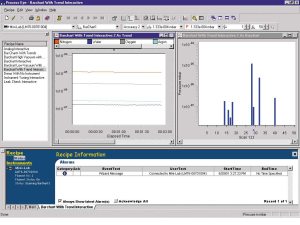

Process Eye™ Professional Control Platform

The Vision 2000-C/E analyzer uses Process Eye Professional, a highly flexible, modular application operating under 32bit or 64bit Windows XP, Vista, Server 2008 or Windows 7. Designed with a “client/server” structure, Process Eye Professional incorporates TCP/IP protocol for full network compatibility.

Creating process recipes is made easy by the Recipe Wizard function, which allows customized warnings and alarm levels, triggered whenever the process exceeds preset levels. The Process Eye Professional recipes also specify the way in which the Vision 2000-C or Vision 2000-E acquires, displays and stores data. Other key parameters, such as ion source settings, can be set via the Process Eye Professional recipe. This allows the user to optimize settings for each phase of the process independently. For example, ideal settings for baseline can be set up in the baseline recipe, ideal settings for process monitoring can be set in the process recipe, etc. Process Eye Professional enhances the Vision 2000-C and Vision 2000-E by providing:

- Automated and intelligent operation of MKS Spectra RGAs with fully customizable controls and alarms

- Flexible scanning

- “Bar Chart”, “Analog” and “Peak Jump” scanning modes which can be mixed and associated with data trend displays

- Intelligent, user defined warnings and alarms

- Can include a suggested diagnosis of the fault condition and a recommendation for its solution

- Data displays in relevant units, such as Torr, mbar or Pa in the process chamber

- Optional ability to read data from other sensors using analog inputs and external events by digital inputs

- Data buffer for quick on-line review of recent data

- Full storage of all data for subsequent review and analysis

The Vision 2000-C™ and Vision 2000-E™ are designed to track levels of various gas species during etch processes and the chamber clean, passivation sequences, and deposition steps for various CVD processes including:

- Titanium nitride (from TDMAT)

- Tantalum oxide (from tantalum precursor)

- Copper (from CupraSelect®)

- HDP of low-k dielectric films

- Atomic layer CVD (ALD) & atomic layer epitaxy

- MOCVD

- Tungsten and tungsten silicide

- Reactive ion etching (RIE)

- Plasma etching

- High density plasma etching

- Microwave etching

Resources

Drawings & CADs

- Vision 2000-C™ and Vision 2000-E™ RGA Dimensional Drawing (155.6 kB, PDF)

Literature

- Vision 2000-C™ and Vision 2000-E™ RGA for CVD and Etch Processes (347.4 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity