FTIR-based Continuous Emission Monitoring System Integrator Kit

Overview

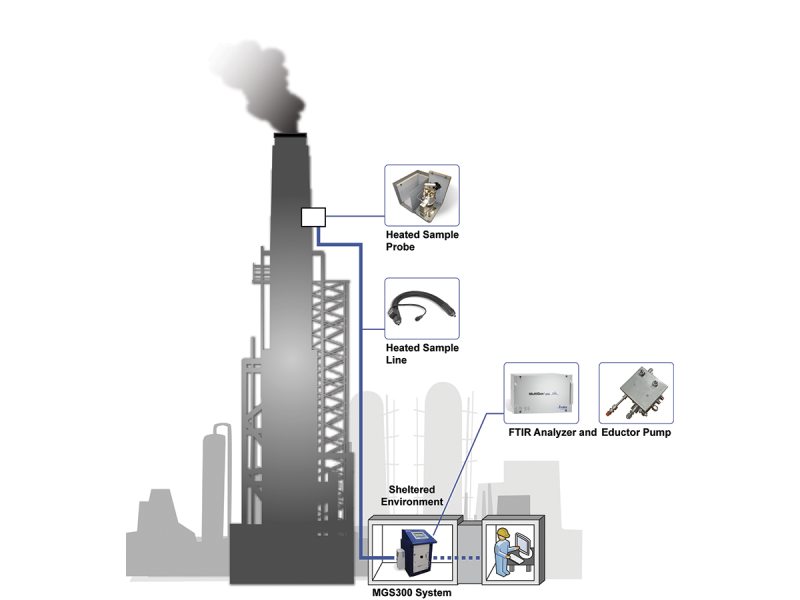

The MGS300-KIT provides integrators with access to key components used in the Continuous Emissions Monitoring system (CEMS), the MGS300, which has achieved TÜV and MCERTS certification in accordance with requirements of the DIN EN 15267-3 standard. The MGS300 system is a fully turn-key system designed to provide reliable monitoring of emissions from stationary sources, including municipal and industrial waste incinerators, power plants, cement kilns and other fixed location sources of emissions.

- Kit components are integral to MGS300 TÜV and MCERTS certification

- Modular kit design allows easy integration of critical MGS300 system components into CEMS

- Addresses a wide range of gas components, with direct analysis of hot, wet sample streams

- Extractive sampling system components operate at an elevated temperature to eliminate sample condensation

- Selection of "wetted part" materials ensure sample integrity

- Highly reliable kit components enable long-term continuous emissions monitoring with minimal maintenance

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

MGS300-KIT CEM System Integrator Kit, FTIR-based Continuous Emission Monitoring |

|

Specifications

-

Measurement TechniqueHigh resolution FTIR spectrometry

-

Spectral Resolution0.5 cm-1

-

Infrared SourceSilicon carbide @ 1200°C

-

Reference LaserHelium Neon Laser (15798.2 cm-1)

-

DetectorThermoelectrically (TE) cooled MCT (Hg Cd Te)

-

Spectrometer Purge Flow0.2 L/min of dry N2 or CO2 free clean, dry air with dewpoint below -70°C

-

Optics Purge Flow0.2 L/min of dry N2 or CO2 free clean, dry air with dewpoint below -70°C

-

Enclosure19-inch rack mount chasis

-

Dimensions17.5 in. W x 12.5 in. H x 25.5 in. D

-

Power Requirements230 VAC/50Hz or 115 VAC/60Hz

-

Weight50 Kg (110 lbs)

-

Gas Cell Pathlength and VolumePath Length: 5.11 m

-

Fittings1/4 inches Swagelok®

-

MirrorsMgF2 coated mirrors

-

WindowsBaF2

-

O-ringsViton®

-

Operating Temperature5° to 40°C

-

ComplianceCE

Features

System Components

The key modules that make up the MGS300 system are now available in the form of a kit (MGS300-KIT) allowing integrators to incorporate the same core elements of the MGS300 system performance and reliability into their own continuous emissions monitoring systems. The MGS300-KIT is comprised of the MultiGas 2030 CEM-Cert FTIR spectrometer, along with the main components used in the MGS300 system extractive sampling system, including the MGS300-SP sample probe, MGS300-EP eductor pump module and the MGS300-HL heated line assembly.

These performance-critical extractive sampling system components are integral to the MGS300 system’s achievement of TÜV and MCERTS certification. These components are designed to operate at an elevated temperature so that all sample species remain in the gas phase with no sample condensation. The materials used in their construction (wetted parts) have been carefully selected to ensure that sample integrity is maintained at all times and that no selective absorption or desorption of gas components occurs under normal monitoring conditions.

MultiGas™ 2030 CEM-Cert FTIR Spectrometer

At the heart of each MGS300 system lies a MultiGas 2030 CEMCert FTIR spectrometer. The MultiGas 2030 CEM-Cert uses high resolution FTIR technology to enable the monitoring of a broad range of gas components over the most challenging of certification ranges available from a single FTIR analyzer. It is able to achieve this with minimal cross-interference effects from either water (up to 40%) or other potentially interfering species. Furthermore, by using permanently stored internal reference calibration spectra, the need for costly calibration gas mixtures is all but eliminated.

- Critical component of the TÜV & MCERTS certified MGS300 system with the proven capability to meet DIN EN 15267-3 standard requirements

- High resolution FTIR technology (0.5 cm-1) for accurate gas composition measurements with low cross-interference effects

- Measures multiple gas components over a wide range of compositions eliminating the need for multiple instruments

- Permanent reference calibration spectra all but eliminates the need for calibration gases

- Software with communication protocol options for integration with a CEMS control platform

MGS300-SP Sample Probe

The MGS300-SP is a heated gas sample probe designed for continuous use in extractive sampling systems. The MGS300-SP may be used even when the sample contains dust, aerosols, water vapor and high dew point corrosive gases and must be kept above its dew point to prevent corrosion and sample degradation prior to analysis or sample conditioning. The MGS300-SP incorporates a corrosion resistant, heated PTFE filter element which is easily replaceable. The filter element is mounted in a thermally isolated and electrically heated stainless steel housing, protected by a weather proof enclosure. When installed on the MGS300 system, the temperature is regulated by a maintenance free, electronic temperature controller with under temperature alarming. A heated sample line may be directly connected to the probe using a demountable PG 42 cable conduit on the probe’s housing.

- Used as part of the TÜV & MCERTS certified MGS300 system

- Easily replaceable PTFE filters

- Heated gas path 180°C to 200°C (356°F to 392°F)

- Stainless steel construction

- Calibration gas port

- Separate temperature controller available

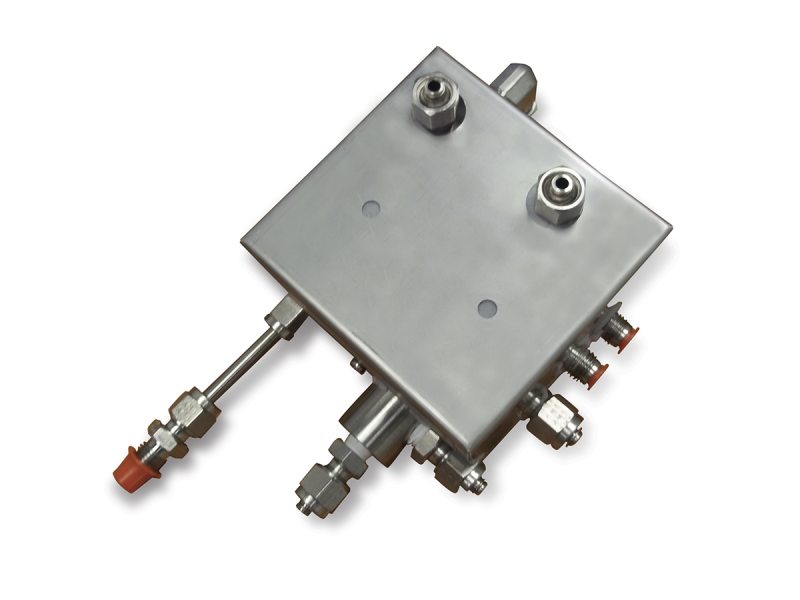

MGS300-EP Eductor Pump Module

The MGS300-EP is a heated eductor pump module designed for the transport of hot, wet and corrosive combustion exhaust gases to the MultiGas 2030 CEM-Cert FTIR analyzer. The unique MGS300-EP module has no moving parts and ensures consistent sample gas flow to the analyzer while offering the low maintenance required for long-term Continuous Emissions Monitoring applications.

- Used as part of the TÜV & MCERTS certified MGS300 system

- Air flow driven eductor pump

- No moving parts, low maintenance

- Calibration gas port

- Heated gas path 180°C to 220°C (356°F to 428°F)

- Stainless steel construction

- Integrated sintered metal dust filter

- Sample flow alarm capability

- Heated T-connector for other hot analyzers, e.g. FID

MGS300-HL Heated Line Assembly

The MGS300-HL heated line assemblies ensure that sample species remain in a gaseous state during transport from the MGS300-SP sample probe to the MultiGas gas cell. These lines are extremely robust, with high quality materials and components used throughout in their construction. The MGS300-HL design ensures that an even temperature is maintained along the entire length of the line, with silicone thermal insulation used to minimize heat losses.

- Used as part of the TÜV & MCERTS certified MGS300 system

- Rugged construction for long lifetime

- Excellent thermal insulation – low heat loss

- Stainless steel inner core for optimum CEMS gas analysis performance

- Integral temperature sensor for effective temperature control

Ultra-High Velocity

Ultra-High Velocity