220DD 1-25000 Torr Heated (45°C) Baratron® Differential Capacitance Manometer

Overview

The 220DD Baratron® differential capacitance manometer is temperature controlled to 45°C for use in demanding, harsh environments. The Baratron® 220 includes all signal conditioning, power supply and is enclosed in a rugged, NEMA1 approved housing. It is available in ranges from 1 to 25,000 mmHg/Torr (500 psia). Accuracy is ±0.15% of Reading.

- Temperature controlled to 45°C for 0.15% of reading accuracy

- Simultaneous 0-10 VDC and 4-20 mA outputs proportional to differential pressure

- NEMA 1 enclosure for sensor protection in harsh industrial environments

- Usable resolution of 1 part in 10,000 covers a wide range of pressures

Products

| Compare | Description | Drawings, CAD & Specs | Availability | Price | |||

|---|---|---|---|---|---|---|---|

|

Vacuum Pressure Transducer, Differential, 1 Torr, 0.5 in. Tube, NEMA1, 45C

$2,536

|

220DD-00001A2B Vacuum Pressure Transducer, Differential, 1 Torr, 0.5 in. Tube, NEMA1, 45C | $2,536 |

|

|||

|

Vacuum Pressure Transducer, Differential, 1 Torr, 8 VCR, NEMA1, 45C

$2,729

|

220DD-00001B2B Vacuum Pressure Transducer, Differential, 1 Torr, 8 VCR, NEMA1, 45C | $2,729 |

|

|||

|

Vacuum Pressure Transducer, Differential, 1 Torr, NW16 ISO-KF, NEMA1, 45C

$2,729

|

220DD-00001D2B Vacuum Pressure Transducer, Differential, 1 Torr, NW16 ISO-KF, NEMA1, 45C | $2,729 |

|

|||

|

Vacuum Pressure Transducer, Differential, 10 Torr, 0.5 in. Tube, NEMA1, 45C

$2,536

|

220DD-00010A2B Vacuum Pressure Transducer, Differential, 10 Torr, 0.5 in. Tube, NEMA1, 45C | $2,536 |

|

|||

|

Vacuum Pressure Transducer, Differential, 10 Torr, 8 VCR, NEMA1, 45C

$2,729

|

220DD-00010B2B Vacuum Pressure Transducer, Differential, 10 Torr, 8 VCR, NEMA1, 45C | $2,729 |

|

|||

|

Vacuum Pressure Transducer, Differential, 10 Torr, NW16 ISO-KF, NEMA1, 45C

$2,729

|

220DD-00010D2B Vacuum Pressure Transducer, Differential, 10 Torr, NW16 ISO-KF, NEMA1, 45C | $2,729 |

|

|||

|

Vacuum Pressure Transducer, Differential, 100 Torr, 0.5 in. Tube, NEMA1, 45C

$2,536

|

220DD-00100A2B Vacuum Pressure Transducer, Differential, 100 Torr, 0.5 in. Tube, NEMA1, 45C | $2,536 |

|

|||

|

Vacuum Pressure Transducer, Differential, 100 Torr, 8 VCR, NEMA1, 45C

$2,729

|

220DD-00100B2B Vacuum Pressure Transducer, Differential, 100 Torr, 8 VCR, NEMA1, 45C | $2,729 |

|

|||

|

Vacuum Pressure Transducer, Differential, 100 Torr, NW16 ISO-KF, NEMA1, 45C

$2,729

|

220DD-00100D2B Vacuum Pressure Transducer, Differential, 100 Torr, NW16 ISO-KF, NEMA1, 45C | $2,729 |

|

Configuration Options

The following options are available for 220DD Baratron® Differential Pressure Transducers

Ordering Code Example: 220DD00100A2B

| Configuration Option | Option Code |

|---|---|

| 220DD Differential Capacitance Manometer | 220DD |

| Range Full Scale | |

| 1 Torr | 00001 |

| 10 Torr | 00010 |

| 20 Torr | 00020 |

| 100 Torr | 00100 |

| 1000 Torr | 01000 |

| 5000 Torr | 05000 |

| 10000 Torr | 10000 |

| 15000 Torr | 15000 |

| 20000 Torr | 20000 |

| 25000 Torr | 25000 |

| Fittings | |

| 0.5 in. OD tube | A |

| 8 VCR female | B |

| 1.33 in. OD CF, rotatable | C |

| NW16 ISO-KF | D |

| Power Requirements | |

| 115/230 VAC | 2 |

| Analog Output | |

| 0-10 VDC and 4-20 mA | B |

Specifications

-

TypePressure Transducer and Transmitter

-

Sensor TypeIndustrial Capacitance Manometer

-

Measurement TypeDifferential

-

Full Scale Pressure Ranges1, 10, 100, 1000, 5000, 10000, 15000, 20000, 25000 Torr

-

Sensor TemperatureControlled to 45°C

-

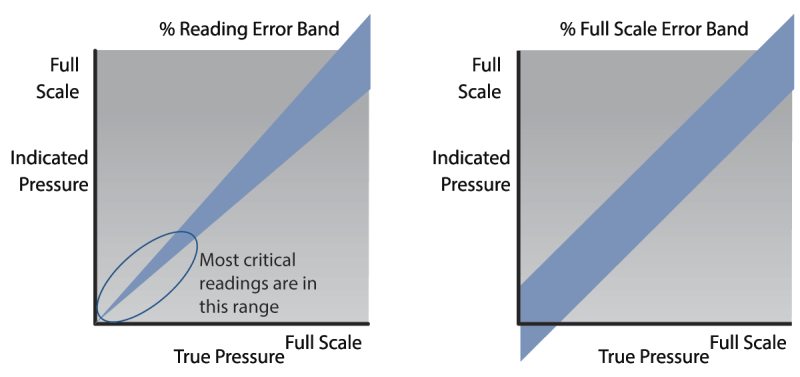

Accuracy±0.15% of Reading (± temperature coefficients)

-

Resolution0.01% of Full Scale

-

Analog Output0 to 10 VDC into > 10K Ω load and 4 to 20 mA into <500 Ω load

-

Electrical ConnectorMating connector P/N MS306A-14S-6S; MKS Connector Kit 220C-AC-K1

-

Zero Temperature Coefficient0.008% of Full Scale/°C for 1 Torr

0.005% of Full Scale/°C > 1 Torr -

Span Temperature Coefficient0.02% of Reading/°C

-

Exposed MaterialsPx side: Inconel

Pr side: Inconel, Ceramic, Palladium, Stainless Steel, Glass -

VolumeMeasurement Side (Px): 7.0 cc

Reference Side (Pr): 19.0 cc -

Overpressure Limit120% of Full Scale or 20 psi (140 kPa), whichever is greater For Full Scale ranges less than 1000 Torr

-

Power Requirements115/230 VAC, 50/60 Hz

-

Enclosure RatingNEMA 1

Features

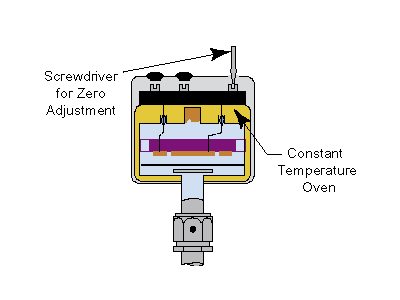

Internally Heated to 45°C

These capacitance manometers are temperature controlled to 45°C for improved accuracy. Unheated versions are exposed to ambient temperature variations which can degrade the sensor accuracy. These devices have the sensor enclosed in a volume that is maintained at a constant temperature above ambient. This solution improves the manometer’s accuracy and repeatability and lowers instrument drift by reducing or eliminating process contamination within the manometer. Heated manometers are recommended for applications that require maximum accuracy and repeatability, operate above ambient temperature and for those processes that employ hot gases.

Differential Pressure Measurement

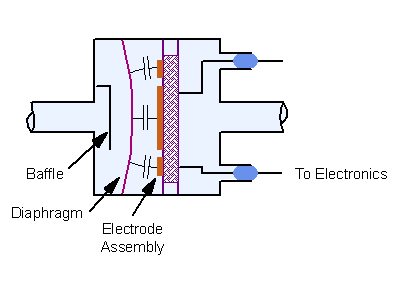

Differential capacitance manometers can be connected to any pressure or vacuum source for use as the reference pressure. These manometers read the difference in pressure between the inlet tube and the reference cavity at the backside of the electrode. Differential pressure transducers can be used to measure either the true differential pressure or vacuum between two locations, or the reference side of the product can be left open to provide a true reference to local atmospheric pressure. Applications include air and gas flow measurements for filters and analytical systems, downstream pressure control in thin film processing systems, and automated leak testing systems.

All-Inconel® Wetted Surfaces

These pressure transducers feature all Inconel® construction of the pressure sensor allowing it to operate without damage in virtually any chemical environment, including exposure to halogens, deionized water and steam, and ozone.

0-10 VDC and 4-20 mA Pressure Outputs

These Baratron® capacitance manometers feature two simultaneous 0 to 10 VDC and 4 to 20 mA analog pressure outputs to interface with common process control systems. The 0-10 VDC signal allows it to be used as a pressure transducer, while the 4-20 mA signal supports use as a pressure transmitter.

NEMA 1 Rated Enclosure

All pressure sensor components and electronics are housed in a rugged, NEMA 1 rated enclosure for protection when used in harsh industrial environments.

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Resources

Manuals

- 220D Baratron® Capacitance Manometer Manual (562.3 kB, PDF)

- 220 Capacitance Manometer Pin-outs (23.2 kB, PDF)

Ultra-High Velocity

Ultra-High Velocity